Armadillo Additive Announces Advanced Additive Manufacturing Facility

April 1, 2024

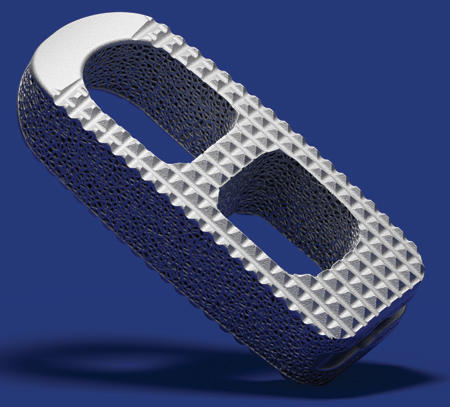

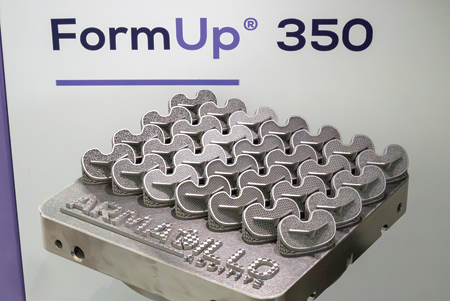

Spinal implants printed on the FormUp 350

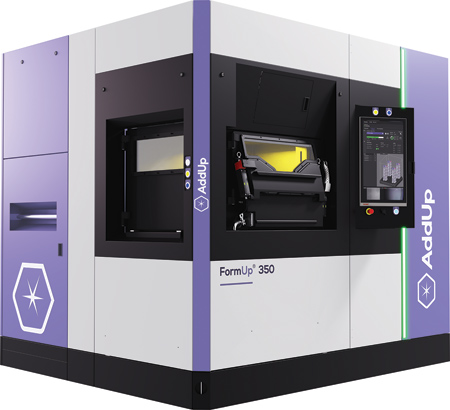

AddUp's FormUp 350 Powder Bed Fusion machine

Texas-based contract manufacturer Armadillo Additive has announced the launch of its new advanced additive manufacturing (AM) facility. The facility is anchored by AddUp's FormUp 350 Powder Bed Fusion (PBF) machine, which offers a substantial build volume, high performance and productivity and enhanced surface finish.

The Armadillo Additive facility specializes in Grade 23 Titanium, offering advanced strength-to-weight ratios and biocompatibility for medical devices. The company's capabilities extend to intricate lattice design work, optimizing structural integrity and material efficiency. Complemented by comprehensive in-house services like laser marking, heat treatment and bead blasting, it provides end-to-end solutions that are designed to meet the rigorous demands of medical engineering.

"We chose AddUp's FormUp 350 because it was the only machine on the market able to produce high-quality medical implants at volume with unrivaled surface finish as printed, limiting the need for post-processing. The FormUp 350 is a dream come true for us," said Noah Smith, Armadillo Additive Director of Operations. "It is on the cutting edge from both a software and hardware perspective. The large build volume and quad laser system allow us to get production jobs done faster than the competition, while the roller recoater lets us push the design envelope to the next level."

For more information contact:

Armadillo Additive

3410 Plaza East

Granbury, TX 76049

dill@armadilloadditive.com

www.armadilloadditive.com

AddUp

www.addupsolutions.com

< back