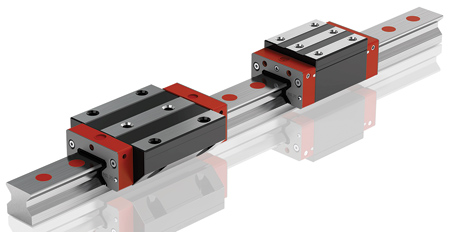

The SCHNEEBERGER MR 30 MONORAIL 30 mm rail and cross roller cartridge moves especially heavy workpieces of up to 150 tons in milling, turning, drilling or grinding machines.

SCHNEEBERGER Inc. has expanded its MONORAIL MR profiled linear guideway series with its MR 30 MONORAIL 30 mm rail and cross roller cartridge. The MONORAIL MR series moves especially heavy workpieces of up to 150 tons with accuracy in milling, turning, drilling or grinding machines.

The MR 30 is designed to deliver higher machining rates, enhanced geometrical accuracy and improved surface quality of machined workpieces in applications ranging from industrial engine production to power plant construction to aerospace engineering and other heavy machinery construction.

"The series features superior O-geometry, rather than the more-prevalent X-geometry, for extreme accuracy in positioning," said a company spokesperson. "Other series features include high rigidity for improved vibration control, greater dynamic and static load carrying capacity, increased rail straightness and optimized path geometries for rollers and transitions for greater running smoothness, and total carriage enclosure. All sizes in the series (25 mm, 30 mm, 35 mm, 45 mm, 55 mm, 65 mm and 100 mm) are configurable to meet the accuracy class specific to any application-from G3 (standard) to G2 and G1, as well as the highly-accurate G0."

Benefits of SCHNEEBERGER's utilization of O-geometry in the MONORAIL MR series include internal spacing of the load-carrying surfaces in conjunction with 90° offset of the roller tracks, uniform and high absorption of forces from all directions and higher rigidity during workpiece movement.

The series offers: three different preload classes; special set processing through system grinding and paired rails supporting accurate machines; carriage and rail types for attachment from above and from below; through-hardened carriages for long life; single-piece rail lengths of up to 6 m; no change of preload during assembly and operation; no loss of preload for constant machine execution; low drag wipers for protection against the environment and corrosion, with optional especially thin dense chrome plating; a stainless steel cover-strip, various hole plug options for long lifespan of wipers; a variety of coatings for corrosion protection; and a variety of accessories and options. The MR 4S series offers an optimized lubrication system, ease of maintenance, shock resistant and dirt repellent.

For more information contact:

SCHNEEBERGER Inc.

44 Sixth Road

Woburn, MA 01801

800-854-6333

www.schneeberger.com