Doosan Chooses ModuleWorks Cutting Simulation Technology

April 1, 2021

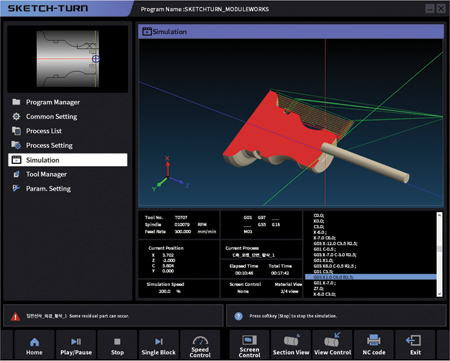

Sketch Turn with integrated MW Cutting Simulation

Doosan Machine Tools has integrated the ModuleWorks cutting simulation technology into its Sketch Turn product. The ModuleWorks software replaces Doosan's previous cutting simulation engine and is part of Doosan's strategy to optimize the availability and effectiveness of machining information on the shop floor.

Sketch Turn is a highly automated NC programming environment that assists operators in creating and editing machining programs for Doosan turning centers. The integrated ModuleWorks simulation software enhances Sketch Turn with sophisticated stock removal verification for mill, turn and combined mill-turn applications. The graphic simulation and NC program are displayed next to each other on the Sketch Turn interface to enable operators to identify problems and conveniently edit the G-code.

The ModuleWorks simulation provides automatic collision checking between the toolholder, tool shaft and workpiece. A full range of toolpath analysis tools for segment length/type, feedrate and height as well as detailed gouge and excess analyses allow toolpaths to be refined and optimized before machining. All this information is available directly in the Sketch Turn interface for fast and efficient G-code editing on the shop floor.

"We already use the ModuleWorks Collision Avoidance System on our turning centers, so this latest cooperation is a natural continuation of our partnership," said Kyungchul Kang, General Manager (Automation & Smart Factory) at Doosan Machine Tools. "Replacing our current simulation engine with ModuleWorks Cutting Simulation takes Sketch Turn to the next level of development and furthers our strategy of creating a seamless flow of information on the shop floor for right first-time machining."

"Partnerships like this show the importance of working together to combine technologies and develop innovative solutions that take digital manufacturing a step further," said Mark Foti, Head of Digital Factory at ModuleWorks. It is very rewarding to see how our technology helps Doosan to enhance their products and we look forward to the next developments in our technologies."

For more information contact:

Doosan Machine Tools America

19A Chapin Road

Pine Brook, NJ 07058

973-618-2415

DMTA.Marketing@doosanmt.com

www.doosanmachinetools.com

ModuleWorks

info@moduleworks.com

www.moduleworks.com

< back