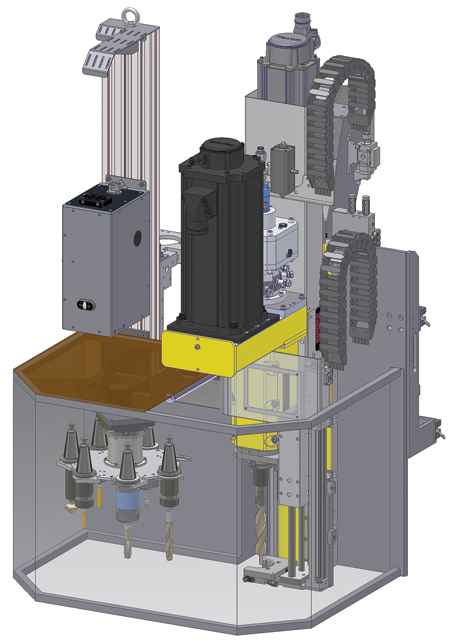

The Auto Drill 30, an optional station for ESAB cutting automation systems, can drill holes with diameters up to 30 mm, as well as tap, countersink and counterbore.

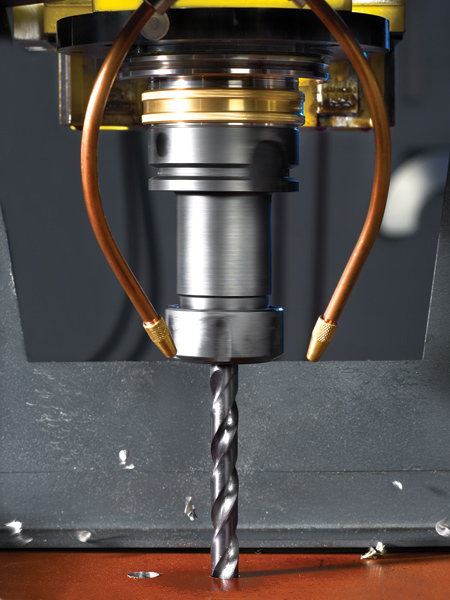

The Auto Drill 30 includes through-the-tool cooling as well as external cooling.

ESAB Welding & Cutting Products offers its Auto Drill 30 fully-automated drilling system capable of drilling holes with diameters up to 30 mm through plate thicknesses up to 50 mm, depending on material type. The system uses a new spindle design to expand drilling diameter and add capabilities.

Equipped with a seven-tool changer to accommodate seven different tools within the same program, the Auto Drill 30 can also tap, countersink and counterbore. The Auto Drill 30 is an available option for ESAB's Suprarex HDX and NUMOREX automated cutting machines, making it suitable for steel service centers, large manufacturers, bridge builders and structural steel companies. It can be used in combination with stations for plasma beveling, oxy-fuel cutting, inkjet marking and pin stamping.

"Combining process technologies enables users to produce finished or nearly-finished products on a single automation system," said Steve Zlotnicki, Global Product Manager, ESAB Cutting Systems. "The Auto Drill 30 is another way we help fabricators increase productivity, safety and accuracy by reducing material handling."

The Auto Drill 30 system's tool changer is mounted on a carriage attached directly to the drill station, allowing tool changes to happen very quickly, without moving or unclamping the drill station itself. This increases productivity because the machine and tool station do not have to move to a different location to change tools, and it increases productivity because there is no need to re-orient the plate to ensure accuracy. A laser sensor measure tool confirms tool tip position on every down-stroke, allowing it to detect if the tool is broken.

The Auto Drill 30 includes through-the-tool cooling as well as external cooling. It is equipped with a pneumatic hold-down device to reduce vibration while drilling and has a chip shield for safety to prevent throwing chips. Both the X- and Y-axis have clamps for holding the tool steady while drilling. The system is supplied with drilling parameters for a wide range of hole sizes, making it easy to produce cut parts with precision-drilled holes in a single operation. All drilling parameters are captured and automated by ESAB's on-board Process Database. They can be easily retrieved manually or fully automated by the part program.

For more information contact:

ESAB Welding & Cutting Products

800-ESAB-123 / 864-466-0921

www.esabna.com