The Digital Anatomy 3D printer from Stratasys enables physicians to practice inserting screws for orthopedic applications with biomechanical realism similar to a human anatomy.

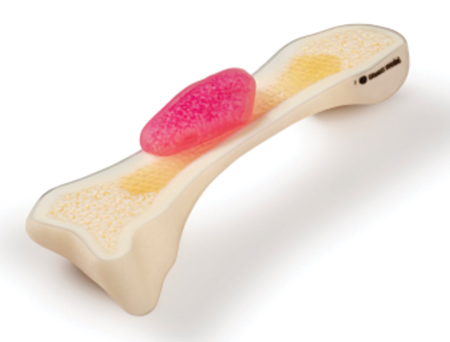

The Digital Anatomy 3D printer from Stratasys produces accurate models of patient bones down to the voxel level, including marrow, and even lets doctors include features like tumors.

Stratasys Ltd. has enhanced its J750 Digital Anatomy 3D printer with advanced bone capabilities that are biomechanically realistic and backed by clinical research. The software upgrade enables the systems to mimic porous bone structures, fibrotic tissue and ligaments so medical professionals can create models that behave just like human bone.

The Digital Anatomy printer when first introduced had an initial focus on mimicking soft cardiology tissues, such as hearts and blood vessels, using Digital Anatomy software and materials like GelMatrix and TissueMatrix. "The technology has helped healthcare providers improve surgical preparedness and medical device makers to conduct testing and train medical professionals on new devices. BoneMatrix material with the enhanced software capabilities extends those benefits to orthopedic applications," said a company spokesperson.

"We believe that better preparation leads to better clinical outcomes," said Vice President Osnat Philipp, who leads the global healthcare team at Stratasys. "The mechanical properties of bone are fundamental to the ability of our skeletons to support movement, provide protection for our vital organs and ultimately affect our quality of life. Being able to 3D print models that are biomechanically accurate and unique to each patient is critical to that preparation."

"Despite the high demand for bone models, traditional model options have serious shortcomings," said the spokesperson. "The medical industry has traditionally used human bone from cadavers, or legacy 3D printing solutions, all of which have proven inadequate. Human bone is expensive, difficult to obtain and hard to acquire with the precise pathology characteristics needed, such as with tumors or reflecting different ages. Off-the-shelf manufactured bone models also lack those patient-specific characteristics, and other traditional 3D printing solutions are biomechanically unrealistic. In contrast, whether inserting a screw or drilling or sawing a bone, medical professionals can expect haptic feedback from Digital Anatomy models that is very realistic, and each model can be created from an actual patient scan."

3D-printed skull and spine models for physician training workshops allow doctors to practice cutting and drilling bones, said a medical director at a children's hospital in Florida. Her focus has been on using state-of-the-art simulation to transform pediatric training and education. "The opportunities seem endless to me because doctors can `operate before they operate,'" she said. "It is going to decrease surgical time, it is going to decrease morbidity and mortality, and help us decrease anesthesia time, which is better for brain development."

"While the 3D printer itself is cutting-edge technology, it is the Digital Anatomy software that unlocks its power," said the spokesperson. "More than 100 sophisticated presets have been developed and refined through years of expert testing, in partnership with top academic medical centers and hospitals around the world." For example, intervertebral discs can be printed normal or degenerated. The joints between vertebrae can be printed in varying degrees of stiffness. The denser structure of skull bone is differentiated from general bones. Long bones can be printed with varying amounts of marrow. Different combinations of materials are produced at a 3D voxel level to ensure the right biomechanical properties.

Researchers at the Computational Mechanics and Experimental Biomechanics Lab at Tel Aviv University conducted a clinical evaluation of the characteristics of bone models that were 3D printed on the Digital Anatomy system, specifically focusing on how accurately they replicated screw pull-out force and driving torque using cortical and cancellous screws. The 2020 study concluded that orthopedic screws pull-out force in the 3D-printed models had a similar haptic response to human cadaver bone.

A second study conducted in 2020 by researchers at the Technion Institute of Technology's Materials Science and Engineering Laboratory in Israel demonstrated the mechanical accuracy of 3D-printed spine models compared to cadaver spines. The study was able to demonstrate that the 3D-printed models of lumbar vertebrae accurately represented the range of motion compared to published literature on human spines.

For more information contact:

Stratasys Ltd.

7665 Commerce Way

Eden Prairie, MN 55344

877-489-9449 / 952-937-3000

info@stratasys.com

www.stratasys.com