The MS24-6 features an open front, which aids accessibility and ergonomics and allows for various automation options.

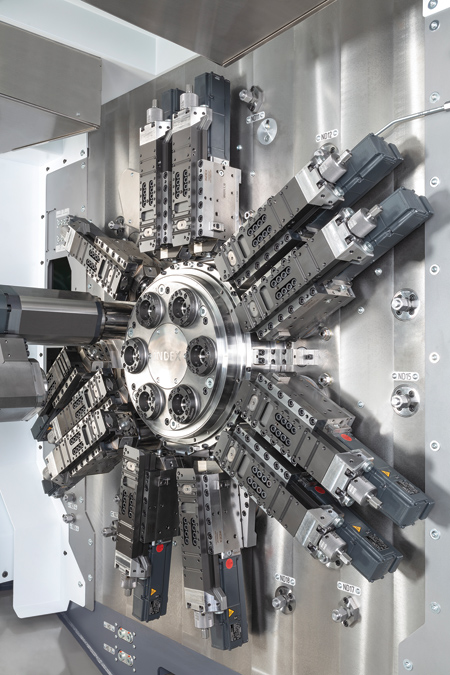

Quick clamping system for slides, with W-serration: with this INDEX development, toolholders can be set up in a very short time without complicated aligning work. The exact alignment is already predetermined in the W-serration of the slide and the positive teeth of the toolholder.

The INDEX MS22 multi-spindle machine now has a successor: the new CNC-controlled MS24-6 multi-spindle automatic lathe. The new machine is slightly larger in maximum bar diameter, but more compact overall and with features designed for economical turning operations as well as fast set-up.

"The trend toward smaller batch sizes is also affecting the market for multi-spindle automatic lathes," said a company spokesperson. "Whereas machines used to produce many millions of parts throughout the year without having to be retooled, it is now common for contract lathe operators to have to retool their multi-spindle machines every two to three days. Set-up times therefore have a significant impact on unit costs. Anyone using a data acquisition system today will see these figures calculated down to the very last detail."

Karl-Heinz Schumacher, Head of Development and Design of Multi-Spindle Machines at INDEX, said an optimized set-up concept is therefore essential when looking to the future: "Batch sizes are going to get even smaller," he said. "This means we need to devise solutions that speed up tooling and set-up, and-no less important-simplify these processes while maintaining a high-precision result. After all, well-trained staff are becoming increasingly rare worldwide."

Quick Clamping System with Integrated W-Serration

The development teams at INDEX have included a range of solutions on the new MS24-6 multi-spindle automatic lathe. One feature is the INDEX quick clamping system with integrated W-serration on the cross slide. Instead of the previously common dovetail system, each cross slide now features a W-serration to simplify micrometer-precise alignment of the toolholder. The W-serration eliminates the degree of freedom in X, meaning that the operator can simply attach the toolholder, which is already preset in the X and Y directions. It is attached using a quick clamping system developed by INDEX that fixes the holder in position using a tie rod and a pre-tensioned wedge rod. "All that is needed is a quick turn with the wrench to ensure the firm contact required for use. This makes the operator 50% faster than when changing the holder the conventional way, and practically eliminates the risk of errors," said Schumacher.

INDEX has developed turning toolholders, drill holders and double drill holders for these slides with W-serration, which are now aligned in advance on the presetting unit instead of in the machine. "Dimensions are transferred exactly due to the W-serration," said the spokesperson. "With the double drill holders, this results in a reduction of set-up times from up to two hours to a maximum of 10 minutes. All of the live units required for milling, polygonal turning and drilling, for example, are also available with W-serrations, meaning they can be precisely placed on the new slide."

Schumacher said, "Despite all of these improvements and innovations, we took care to ensure that the previous toolholders of the MS22-6 can still be used. However, they do not have the new set-up advantages."

Modern Multi-Spindle Machine for Demanding Turned Parts

Designed using a modular principle, the new INDEX MS24-6 multi-spindle automatic lathe (max. bar diameter 24 mm, for chuck parts 50 mm) fits into the niche between the MS16-6 or MS16-6 Plus and the MS32-6. While the INDEX MS16 is suitable for simpler machining tasks and very large batches due to the use of grooving and boring slides, the new MS24-6 is designed for medium to highly demanding machining tasks. The machine features six work spindles and 12 cross slides with NC axes in X, Z, and Y (4x), as well as one or two synchronous spindles for rear-end machining. The machine can be used either with six spindles or two times three spindles. Double rear-end machining is also possible. Live tools, a C-axis and a Y-axis provide users with a broad range of machining options, such as off-center drilling, threading, contouring, gear hobbing or polygonal turning.

The key component of the INDEX MS24-6 is the fluid-cooled spindle drum with its optimized thermal growth and pause jump behavior. The drive power is 8.7 kW at 100% DC and 15 kW at 25% DC per spindle. Speeds of up to 10,000 RPM allow for a wide range of machining options, including aluminum parts.

"With regard to the clamping systems, the MS24-6 opens up new possibilities," said Schumacher. "The smaller machines, like the MS16 or the MS22, feature only tension clamping in the form of a traditional collet. Chucked parts are usually clamped with a standard or special jaw chuck. For our new MS24-6, we are now also offering collet clamping with Axfix TOPlus24. This system is based on compression clamping, which prevents axial displacement and achieves maximum concentricity. The clamping device is therefore particularly recommended for high-precision, pre-machined semi-finished parts that are inserted by a robot."

Intelligent Automation

"Robot automation is indispensable for the machining of demanding chucked parts. In the solution provided by INDEX, the robot works together with a swivel disk that functions as an interface to an external handling system or other customer-specific automation equipment," said the spokesperson. A standardized communication interface is available. The robot integrated in the machine places the finished parts on the swivel disk, at the same time picking up raw parts for insertion.

INDEX also offers other, simpler solutions for automated part removal when bar loading magazines are used. "Since parts produced today cannot be allowed to have even the slightest scratch, discharge via the swiveling synchronous spindle, a chute and a conveyor belt is in many cases no longer adequate. That kind of system is, however, still available," said the spokesperson.

The spokesperson continued, "A significant improvement-especially for relatively long parts such as shafts-is provided by a new INDEX solution that can be fitted to the MS24-6. An additional swivel unit takes the cut part from the synchronous spindle and places it in the correct position on the conveyor belt, which is responsible for transporting it out of the machine."

A similar effect is achieved with orderly part removal via an intermediate gripper, to which the synchronous spindle transfers the cut part in a first handshake. The synchronous spindle is then immediately available for the next machining operation. A linear unit removes the part from the intermediate gripper and moves it out to the handling cell, practically at the same time. This reduces time for full part handling to less than 5 seconds.

Further Highlights

Complementing the INDEX MS24-6 CNC multi-spindle automatic lathe is the INDEX MBL24-6 bar loading magazine, which offers all of the usual MBL benefits regarding smooth bar movement and vibration reduction during machining. It is available as a bundle loader and a bar loader in sizes 3300 and 4300.

"With fluid cooling of the spindle drum, counter spindle and control cabinet, INDEX achieves optimum thermal stability in the MS24-6 multi-spindle automatic lathe, which is of particular significance in view of the machine's compact design," said the spokesperson. "This unique feature makes it possible to maintain extremely tight tolerances during machining. The MS24-6 also features unique warm-up performance. The machine takes on a constant temperature within a very short time and without requiring lengthy corrections by the operator."

The fully pivoting operating panel with the INDEX iXpanel allows easy operation of the MS24-6. Building on the Siemens S840D sl (Solution Line) controller, the operating concept developed by INDEX simplifies set-up and tooling.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

us.index-traub.com

SOUTHWEST

NM

AME, Inc.

5770 Clarkson

Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AR, LA

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

TX

Prosper Machine Tools, LLC

7415 Whitehall Street

Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

SOUTHEAST

AL, FL (Panhandle), MS, TN

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

NORTHEAST

CT, ME, MA, NH, W. PA, RI, VT

INIRAM Precision Machine Tool Inc.

333 North Main Street

Middleton, MA 01949

978-854-3037

www.iniram.com

DE, MD, NJ, S. NY, E. PA

Single Source Technologies, Inc.

2192 Winterberry Court

Warrington, PA 18976

610-430-3670

www.singlesourcetech.com

MIDWEST

S. IL, KS, MO

Dynamic Machine Tool, Ltd.

84 Hubble Drive

Suite 200

St. Charles, MO 63304

636-447-2900

www.dynamicmachinetool.com

N. IL

Integrated Machinery Systems

101 North Prospect Avenue

Itasca, IL 60143

630-250-8305

www.imscnc.com

MI

Methods & Equipment Associates

31731 Glendale Avenue

Livonia, MI 48150

734-293-0660

www.methods-equipment.com

MI (Upper Peninsula), E. WI

Premier Machine Tool Midwest

PO Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com

IN, KY, OH

Technical Equipment

10165 International Blvd.

Cincinnati, OH 45246

800-852-0582

www.techequip.com

WEST

CO, WY

AME, Inc.

5770 Clarkson, Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AZ

CNC PROS

1502 N 17th Ave.

Phoenix, AZ 85007

602-332-5815

www.cnc-pros.com

N. CA, NV (Reno & Carson City)

CNC Solutions

1011 Pecten Court

Suite A

Milpitas, CA 95035

408-586-8236

www.cncsolutions.biz

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street East

Fife, WA 98424

253-926-6868

www.ellismachinery.com

S. CA, NV (Clark County)

Protek CNC

25 W Easy Street

Suite 306

Simi Valley, CA 93065

805-579-9995

www.protekcnc.com