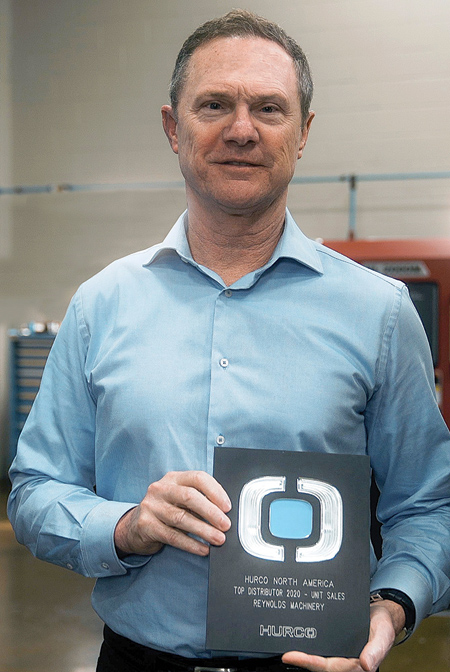

Scott Mays, President of Reynolds Machinery, holds the company's Hurco 2020 Top Unit Sales Award for North America. The custom-designed award was machined on a Hurco with special help from Online Metals and John Force Racing.

Hurco has announced that Reynolds Machinery, the exclusive distributor for Hurco CNC machine sales and service in Ohio, won the 2020 Top Unit Sales Award for North America. Reynolds Machinery has been representing Hurco in the Buckeye State since 1996.

Hurco representatives presented Reynolds Machinery with their award at the distributor's showroom and technical center in Dayton, OH, with the assistance of the Hurco Job Shop Automation Collaborative Robot.

Scott Mays, President of Reynolds Machinery, said, "We are very proud to win the #1 distributor award. We are a competitive group here at Reynolds and the entire team worked very hard all year, so it means a lot to get the win. We are proud to represent Hurco CNC machines. They are well built and the control has the versatility and features shops need to stay competitive and increase productivity and profitability."

Scott Camloh, National Sales Manager for Hurco, said, "Reynolds Machinery's winning formula serves their customers well because they focus on support and service after the sale. Not only are they extremely knowledgeable about Hurco products and the advantages of the Hurco control, they are responsive to their customers and understand how to help them gain the greatest benefits from the powerful technology that is inherent to Hurco CNC machines."

While Reynolds has always been near the top, and often took 2nd place during the past 25 years representing Hurco, this is their first time in the #1 spot. This is also the first year Reynolds has been able to offer customers the Hurco Automation Package from ProCobots. Hurco's Practical Job Shop Automation package integrates the programming of the collaborative robot into the Hurco control.

"The biggest advantage of the Hurco Automation package is the ease of programming and the flexibility it gives shops. If you can program a Hurco, you can program the cobot, which eliminates the need to call an integrator each time you set up a new job. It makes automation practical and easy, especially for high-mix manufacturing environments," said Mays.

For more information contact:

Scott Mays

Reynolds Machinery, Inc.

760 Liberty Lane

Dayton, OH 45449

937-847-8121

scottmays@reynoldsmachinery.com

www.reynoldsmachinery.com

Hurco Companies, Inc.

One Technology Way

P.O. Box 68180

Indianapolis, IN 46268

800-634-2416

info@hurco.com

www.hurco.com