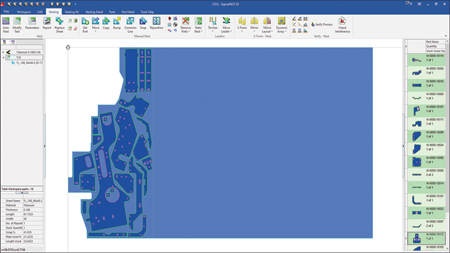

Version 20.2 integration of SigmaMRP and SigmaNEST allows visual inspection of parts on the quote. Part documents can be attached for reference in shop floor applications.

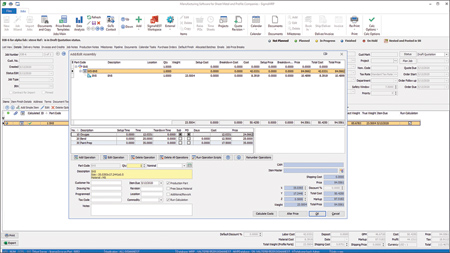

SigmaQUOTE provides nested cost and part cost as well as inventory needed for the job.

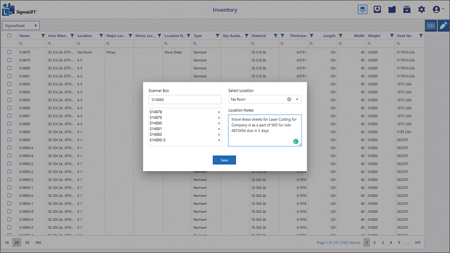

New SigmaLIFT shows all available batches for transfer and bar code tracking.

SigmaTEK Systems has announced the addition of its Business Systems Suite integrated alongside the flagship SigmaNEST product portfolio in Version 20 Service Pack 2 (SP2).

"This latest release of advanced CAD/CAM, Shop Floor Control and now Business Systems brings a full range of fabrication optimization and data management features inside one familiar user interface," said a company spokesperson. "Familiarity and ergonomics play a large part in programming speed and user ease. The version 20 user interface employs improved navigation and a universal easy-read display throughout all SigmaTEK products to increase user focus and stamina."

SigmaTEK's new quoting tool, SigmaQUOTE, is available as both a freestanding application for the quoting department as well as an add-on module for SigmaNEST programmers. SigmaQUOTE uses the SigmaNEST nesting engine, part database and costing parameters to deliver accurate quotes after a speedy import of part geometry. Full bi-directional integration with SigmaSUITE products offers greater flexibility for a real-world production workflow. Quote workspaces can be modified after job creation, and parts can be added, removed and even re-nested without recreating or reimporting the quote, and then pushed directly into production work orders.

As the core of SigmaTEK business system products, SigmaMRP provides single-source job management throughout manufacturing, from quotation to delivery and invoicing. SigmaMRP integrates with both SigmaSUITE products and other business systems to administer critical business data-including inventory, transactions, customers, suppliers, job status, cost and profitability-and now adds several key improvements.

SigmaMRP's scheduling engine provides better performance for jobs with complex assemblies and sub-assemblies, in addition to subcontract operations. New time controls offer scheduling flexibility around work shifts and employee break periods.

The logistics module streamlines a variety of shipping details such as cost, markups and taxes with automatic cost calculation based on weight of line items in each job. Support for multiple couriers allows individually configured rates for each chosen carrier.

The fully-featured inventory module now allows allocation of material and stock per BOM item for improved granularity, as well as allocation by batch for greater flexibility. Complete integration with SigmaNEST ensures stock is dynamically adjusted when programs are posted, deleted or updated mid-production.

New developments in SigmaTEK shop floor offerings increase the capacity for operators to make the right call on the spot, with access to part documents or the option to book remnants and sheets back to inventory, or create a new job for rejected parts. SigmaLIFT paperless tracking software is now a web application allowing flexibility for remote barcode scanning, and a redesigned display that shows all available batches for transfer.

SimTrans works in the background to create a seamless data link from SigmaTEK applications to sales, inventory, engineering, scheduling, production and MRP or ERP systems. SimTrans supplies data to business systems at different phases of the order process, such as work order completion, material consumption levels and automatic machine operation using batch operations.

In the latest release, CAD/CAM products have added profiling and tooling features, and batch commands for work efficiency and increased machine support. Enhancements for SigmaBEND include improved bend ID and sequence change information, additional support for Accurpress press brakes, and batch commands for part processing and press brake part reports. SigmaCTL and SigmaDEVELOP have both been updated with user enhancements that include improved GUI side panels for all shapes from within the Pipes with Taps section and significant batch capabilities to support part quantity in automation, stock list management and program posting.

SigmaNEST CAD/CAM developments include added support for ramping when using 3D bevel technology, measuring capability while in assembly mode, support for the latest CAD versions within the CAD Import Plus modules and improved batch processing performance as more parts are added to the SigmaNEST workspace.

For more information contact:

SigmaTEK Systems, LLC

1445 Kemper Meadow Drive

Cincinnati, OH 45240

513-674-0005

info@sigmanest.com

www.sigmanest.com