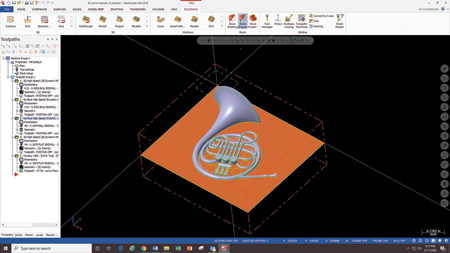

A student-designed French horn, created in Mastercam for SOLIDWORKS.

Catawba Valley machining student Saied Carson uses Mastercam and a Haas Mini Mill to machine an aluminum French horn.

French horn, created in Mastercam for SOLIDWORKS, is machined on a Haas Mini Mill.

CVCC student Saied Carson and instructor Steven Rhoads set up a part for 5-axis machining.

Catawba Valley Community College machining students and instructors: (l-r) Matt Logan, Kameron Lewis, Lee Develle, Larry Luke, Juan Cardenas-Gutierrez, Jim Kondas (instructor), Saied Carson, John Whitlock (instructor), Mike Licause, Ian Ray, Ben Parks, Tony McDaniel, Cristain Tamas, Andrew Smith, Tinsley Armstead, Tate Blanton, Rex Robinette, Dawson Gragg

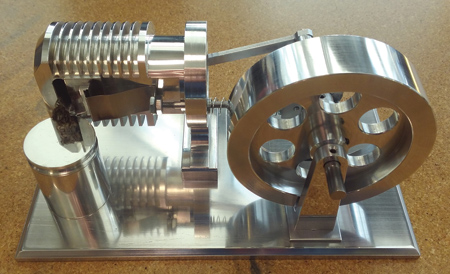

Design and production of a Stirling engine was a curriculum requirement for Catawba Valley Community College machining students. This year, one student's Fire-eater engine, pictured, took second place in the 2020 Phillips Machinist Cutting Edge Parts Competition: Student Edition.

After the economic recessions of the 1990s and early 2000s, and the subsequent relocation of several furniture and textile businesses, Catawba County, NC, is reinventing itself as a manufacturing hub. Training the local workforce is a crucial first step in rebuilding the area economy. An institution at the center of this county-wide effort is Catawba Valley Community College (CVCC), Hickory, NC. Located 55 miles northwest of Charlotte, CVCC was launched in 1959 as a technical school. Today, the college offers multiple vocational programs for its 4,800 students.

CVCC administrators and advisory board members have spent the past five years revamping the school's CNC machining program to meet the needs of the local manufacturing sector. According to Steven Rhoads, Director of the CVCC Integrated Machining Technology program, the skills gap in Catawba and surrounding counties is a critical issue for North Carolina businesses. Because manufacturers are struggling to fill machinist positions, the college tailored and expanded its continuing education program to include more course offerings and night classes. For example, students can now complete a 10-week machining program and earn a 60-hour certificate.

"Companies are having to hire folks off the street to run CNC machines," said Rhoads. "When manufacturers contact us, we sit down with them and write up a syllabus that includes what they want students to learn in those 10 weeks. We pack in as much as we can, and the companies love it. We are doing this to address the skills gap."

The curriculum prepares students with the analytical, creative and innovative skills to take an idea from concept through design, development and production to finished product. Coursework includes manual machining, computer applications, engineering design, computer-aided design (CAD), computer-aided machining (CAM), blueprint interpretation, advanced computerized numeric control (CNC) equipment, basic and advanced machining operations, precision measurement and high speed multi-axis machining.

CVCC's 87,000 sq. ft. Workforce Solutions Complex houses welding, automotive, HVAC machining and engineering. The machine shop is equipped with manual mills, lathes, saws and grinders as well as CNC machining centers, mills and lathes.

After speaking with area businesses about the college's Machining Integrated Technology curriculum, CVCC instructors investigated CAD/CAM software options to support their equipment investment and best prepare students for machining careers. They soon learned that most local manufacturers use Mastercam (CNC Software, Inc., Tolland, CT) due to its flexibility and network of support. A phone call to Mastercam Reseller Barefoot CNC, in nearby Morganton, was the first step in CVCC's CAD/CAM journey.

"I cannot say enough about Barefoot CNC," said Rhoads. "They are only 30 minutes away so I can easily send my instructors down there for training. Or, if a post-processor is not working, I can call Barefoot and someone will stop by."

In addition to machining certification, CVCC graduates can earn one-year diplomas and associate degrees. An intensive eight-week Mastercam summer class focuses on the use and benefits of the CAD/CAM software. More advanced classes cover Mastercam for SOLIDWORKS, which integrates CAD and CAM so programmers can standardize their CAD file database without compromising NC programming quality. Benefits include streamlined productivity, ease of use, speed and accuracy. Mastercam toolpath technology and post-processors are accessible in a SOLIDWORKS environment. To date, CVCC's hands-on learning approach is a proven method for student success.

Before they begin machining, students study Dynamic Motion technology, which allows them to cut more parts in less time. By taking lighter step-overs and deeper step downs, the maximum amount of material is removed with fewer air cuts, resulting in consistent chip thickness and reduced tool wear and cycle times. To better understand how Dynamic Motion works, students design and manufacture Stirling engines comprised of 20 component parts. This year, one Catawba Valley student's Fire-eater engine took second place in the Phillips Machinist Cutting Edge Parts Competition: Student Edition. This project, along with others, lets budding machinists express creativity while learning programming and machining techniques.

"To learn multi-axis machining and surfacing, they find an image of a surface, a skull or Darth Vader's head, for example, bring it into the software and manipulate it so it can be machined on the multi-axis," said Rhoads. "I have used several different CAD/CAM programs and Mastercam is the easiest to me. Dynamic Milling changed the way that we machine."

In addition to ease of use, the software's flexibility and extensive choice of toolpaths are key features, especially for the novice machinist.

"I am plugged in with Mastercam," said Matt Logan, CVCC Integrated Machining Technology student. "I enjoy it. Everyone has their own way of doing things. I have seen students machine the same part I did, but in a totally different way and get the same result. I think that is kind of cool."

CAD/CAM knowledge and shop floor experience are credentials that manufacturers are looking for, even in entry-level employees. Though expertise is not expected, machining and programming skills are.

"Employers do not expect someone to be an expert, they want someone who can set up a machine, touch the tools off and run a part," said Rhoads. "And if there is a small problem with the program, employers want someone who is able to read the G-code and make an edit at the machine. Manufacturers want students who can make offsets and change part sizes at the machine without having to create an entirely new program. They can use their offsets to manipulate the size of the part or hold a tight tolerance."

A focus on industry needs is central to the CVCC machining program. All four of its instructors came from the private sector and have more than 140 years of combined machining experience. They offer students real-world expertise on machining, tool set-up and overall production knowledge.

"I think that is what separates us," said Rhoads. "We are heavy on the G-code and heavy on the CAM. We have a rolling cart and a laptop for every machine. Our goal is to have a laptop with Mastercam at every machine so while students are machining a part, they are programming the next one."

Catawba Valley Community College offers Apprenticeship Catawba, a partnership between CVCC, local manufacturers and local school districts to offer apprenticeships to area high school students. Tuition and books are free, and an apprentice earns paychecks while earning a degree. The program is also available to companies that want to invest in current employees and need programmers and machinists, allowing manufacturers to forgo the time and expense of on-the-job training for current employees or new hires. An apprentice student can earn Journeyman certification or an Associate in Applied Science, Computer Integrated Machining Technology.

"On-the-job training costs a lot of money," said Rhoads. "Now companies are saving money with continuing education classes. In 10 weeks, students are on the machines, setting up, making offsets and touching tools off. The program was started because of area companies' need for machinists."

CVCC and its apprenticeship partners appeal to high school students by offering affordable career options. Promoting the trades and educating potential apprentices on career choices are receiving positive response. Local manufacturers recruit high school students and hold signing days similar to those held for athletes who commit to playing college sports. Apprentices wear hats from their future employers while their parents stand behind them as they sign employment contracts.

"Upon graduation, a former student can go out and get a really good job," said Rhoads. "The company invests in the student and, hopefully, the student will stay with that company for a long time."

To help make continuing education more affordable, grant funds from the Gene Haas Foundation provide tuition assistance for students enrolling in the Computer Integrated Machining associate degree, diploma or certificate programs. The grant also helps fund National Institute for Metalworking Skills certifications and the college's SkillsUSA state and national competitions.

SkillsUSA is a partnership of students, teachers and industry working together to strengthen America's skilled workforce. It promotes the development of personal, workplace and technical skills grounded in academics. CVCC's SkillsUSA team won the SkillsUSA Championships national competition in 2016, fourth in 2017 and seventh in 2019. Of the 19,000 SkillsUSA chapters in the nation, CVCC is one of three recognized as a Chapter Model of Excellence. For six consecutive years, CVCC has been recognized as the #1 College Chapter of the Year.

"We are really proud of the students-they are hitting the ground running," said Rhoads. "When they leave here, their CAD/CAM and machining skills are amazing. They are having fun and they are getting good jobs when they leave."

For more information contact:

Catawba Valley Community College

2550 US Hwy. 70 SE

Hickory, NC

828-327-7000

www.cvcc.edu

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com