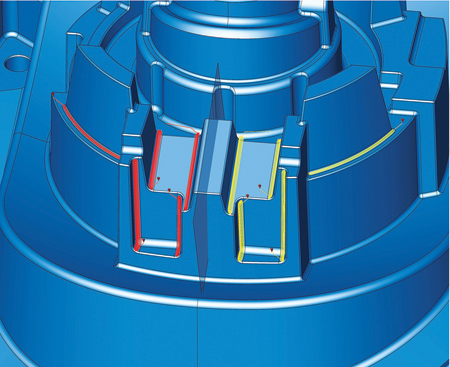

hyperMILL mirror function shortens calculation time.

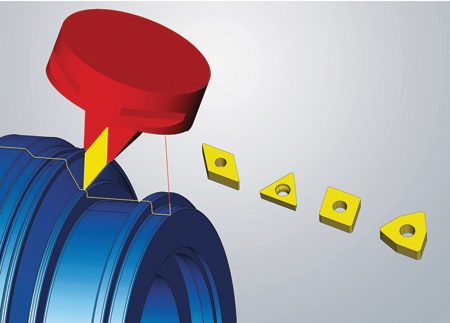

New insert types are available for 3-axis simultaneous turning jobs.

OPEN MIND Technologies AG offers its latest hyperMILL 2020.2 CAD/CAM software suite with new and enhanced features for efficient 3D and 5-axis machining, such as the hyperMILL AUTOMATION Center Advanced option and more.

New features include the addition of plunge-milling cycles to the 3D and 5-axis strategies for machining cutting edges. Material is removed by plunging movements to reduce vibration and improve surface finish-especially helpful for machining edges with steep walls. When 5-axis machining, undercut areas can also be reached by specifying the lateral inclination on the tilted tool. By specifying a distance, circular or linear movement profile, the tool is optimally retracted from the part.

Due to an enhanced mirror path function, users have shorter calculation times and improved process reliability. The mirror path function now enables simple mirroring of previously calculated toolpaths so the machining direction is also mirrored to effectively make climb milling a conventional milling process. hyperMILL also retains the original strong mirror function where toolpaths for symmetrical components are recalculated on the basis of mirrored geometry data.

"We continue to improve the hyperMILL user experience with new, optimized strategies, as well as provide easier to use interfaces and even more efficient filtering and feature management functions," said Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. "Also, enhanced functionality in our Mill-Turn, hyperCAD-S and AUTOMATION Center modules are all key to continually improving the user experience and increasing machining productivity."

When 3-axis simultaneous mill/turning, inserts including round, rhombic, T and W can now be used. Also, unlocking the potential to reach particularly difficult areas, a new function controls the approach and retract movements by applying user-defined curves for turning strategies.

A hyperMILL AUTOMATION Center Advanced option offers numerous additional features and extensive templates to the software's automation capabilities. Templates allow the user to define and standardize complex processes independent of the specific geometry from any one CAD model. All the individual steps for data preparation and programming are defined for applying them to a new model and automatically executing them. For increased efficiency, the user is interactively guided through the automated process steps, and can be prompted to make relevant choices during the automation sequence if desired.

Components can now be modeled parametrically directly in hyperCAD-S, especially helpful for fast, production-related designs. Parametric geometry data used in hyperMILL is associatively linked, and when there are any changes, is automatically updated.

A key strategy in the latest hyperMILL CAM software release is the ADDITIVE Manufacturing process that supports 3D printing and subtractive machining on one machine tool. hyperMILL ADDITIVE Manufacturing technology offers flexible strategies for additive material applications, including filling strategies for both planes and free-form shapes, and in 2D and 3D sections.

Applications also include hybrid machining to fix damaged parts and additive machining of an existing component.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com