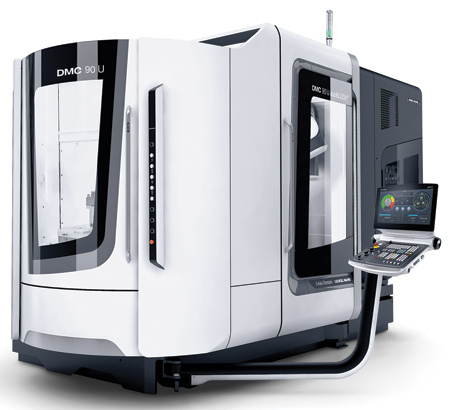

With the DMC 90 U duoBLOCK, DMG MORI has developed a package machine that unites the benefits of the duoBLOCK design.

Steering knuckle for Infinity Red Bull Racing Formula 1 cars

With 20,000 RPM, 130 Nm and 35 kW, the speedMASTER spindle of the DMC 90 U duoBLOCK offers high-performance machining.

The DMC 90 U duoBLOCK from DMG MORI offers 5-axis simultaneous machining with pallet changer and is suitable for die and mold, general mechanical engineering and tool manufacturing. According to the company, its powerful standard equipment, integrated pallet changer and high connectivity make the DMC 90 U duoBLOCK a productive companion in future-oriented production.

The DMC 90 U duoBLOCK features a sturdy design and cooling system engineered for long-term accuracy. Optionally, an inside cooling system with 80 bar and temperature control are available. With 20,000 RPM, 130 Nm and 35 kW, the speedMASTER spindle offers high-performance machining. Optional spindle versions with up to 430 Nm torque are available.

The work area of the DMC 90 U duoBLOCK provides sufficient space for workpieces with a diameter up to 900 mm x 1,450 mm. The maximum workpiece weight is 1,500 kg. The tool magazine is designed for 60 tools-up to 180 pockets are optionally available-and minimizes set-up time in day-to-day production. Furthermore, the optimally accessible pallet changer enables parallel set-up for increased productivity.

The DMC 90 U duoBLOCK is equipped as standard with the intuitive control and operating system CELOS and SIEMENS 840D solutionline, which enable easy integration into increasingly digital production. Alternatively, DMG MORI also offers a HEIDENHAIN TNC 640. The DMG MORI IoTconnector is included in the range of features for optimum digital integration. The sensor package i4.0 offers improved accuracy and increased process reliability. DMG MORI technology cycles such as the 3D quickSET or the maintenance package I4.0 round off the offer.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com