By machining in a single clamping operation (in this case, the machining of an elliptical component), the machining time on the CONTUMAT decreased by at least 30%.

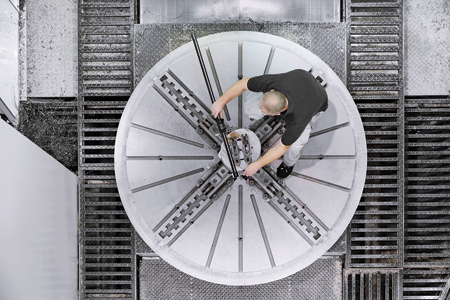

Judith Schmitt, Head of Mechanical Manufacturing, along with Industrial Foremen Norbert Hoffmann and Martin Pach, inspect the large machine table (120 kW drive capacity; 56,100 Nm torque in S1).

"Solid drive technology, paired with modern control technology, provides quick and precise processing," said a Starrag spokesperson.

The CONTUMAT vertical turning lathe meets the IT6 tolerance grade set by the SMS group.

Machine operator Klaus Heinrichs uses CNC and vision system to monitor complete machining.

The 22.9' (7 meter) high CONTUMAT VCE 2400 can be used to process workpieces weighing up to 17 tonnes, with a maximum height of 101.77" (2,585 mm) and a diameter of up to 94.48" inch (2,400 mm).

SMS group, a machine and plant components manufacturer from West Germany, ordered from Starrag a very tall double-column vertical turning lathe (VTL) for complete machining of challenging machine components.

"An important element here is our international, closely integrated manufacturing and workshop network," said Burkhard Dahmen, SMS Chairman of the Board. "We continue to produce challenging machine and plant components in our German plants at a high technological level. Our continued investment in the expansion and modernization of the factories is helping us secure this status."

As part of a modernization drive, SMS has invested around $41 million dollars into production modernization and involvement in Industry 4.0. The company was able to make its plant future-proof within the space of three years as part of this modernization drive, and the effort has paid off. According to Judith Schmitt, Head of Mechanical Manufacturing, this allowed the SMS group to "reduce machining times during operation by up to 50%."

"This is not only a great financial achievement, but also a significant technological and logistical feat," said a company spokesperson. SMS reorganized its set-up and processes with a view toward Industry 4.0 and has exchanged 15 machine tools. One of these machine tools is the Dörries CONTUMAT VC 2400/200 MC V from Starrag.

"The VTL replaces at least two machines we were using to manufacture the workpieces," explained Industrial Foreman Norbert Hoffmann. "It used to be the case that after turning, we would have to carry out drilling and milling on a boring mill or machining center, and then switch back to using the turning lathe."

"The keywords here are `complete machining,'" added Schmitt. "We are now able to carry out turning, drilling, milling and grinding in a single clamping operation."

"Typically, no two Starrag machine tools are alike, and SMS was also particularly impressed with a truly outstanding extra: the CONTUMAT is a tower measuring over 23 feet in height," said the spokesperson. The large machine table (120 kW drive capacity; 56,100 Nm torque in S1) can be used to machine workpieces up to 17 tonnes in weight, with a maximum height of 101.8" and a diameter of up to 94.4". The turning lathe also features a crossbeam that can travel up to 39.3". SMS machines a broad spectrum of materials on the VCE 2400, such as high alloy heat-treatable steels, copper-tin casting alloys and structural steels.

The VCE 2400 is used to create a large variety of cubic and round, small and large, flat and tall components in very small batch sizes that change almost daily. These components will be used almost exclusively in large manufacturing plants at a later date for steel rollers or pipe manufacturing. The VCE 2400 is particularly well suited to machining large components.

Hoffmann said, "The VTL allows us to process very tall components and also penetrate much more deeply, when drilling for example."

Compliance with the company's own standards plays an important role for the machine and plant manufacturer, also taking into account the closely-integrated manufacturing and workshop network. "Starrag has met all the requirements set by the product specifications," said Schmitt.

"Another aspect that made a particularly good impression was that Starrag managed to achieve the high level of geometric accuracy required by us," said Hoffmann. "It is not just any lathe manufacturer that is able to meet the prescribed IT6 tolerance."

Another specification related to ergonomics is that the CONTUMAT was supplied to the customer with complete housing, which works together with the suction device to reliably protect employees from aerosol fumes.

The new plant is also characterized by a comprehensive manufacturer network that follows the guiding principles of Industry 4.0. This also had an impact on the embedding of the machine tools. The requirements set by the product specifications in terms of electronics and interfaces were correspondingly high. As a result of this, the VC 2400 was equipped with laser technology for measuring workpieces and tools, along with systems for recognizing collisions and tool breakage.

The SMS group runs optimization projects with Starrag operators and maintenance staff.

Highlights of the Starrag solution at SMS:

- Productivity doubled, one CONTUMAT VCE replaces two machines

- Processing times reduced by at least 30%

- Maximum levels of geometric accuracy.

Features of the CONTUMAT VCE 2400/200 MC V

- Machining diameter: 94.4" (2,400 mm)

- Turning height: 101.8" (2,585 mm)

- Table diameter: 78.7" (2,000 mm)

- Workpiece weight: 37,478.6 lbs. (17,000 kg)

- Drive capacity (machine table): 120 kW (S1)

- Torque on machine table: 56,100 Nm (S1).

Right-hand crossbeam support:

- X-axis, horizontal: -53.1/+70.9" (-1,350/+1,800 mm)

- Z-axis, vertical: 59.1" (1,500 mm)

- Cutting force during turning: 11,240.4 lbs. (50,000 N)

- Feed force: 7,868.3 lbs. (35,000 N)

- Chain magazine: 100

- Tool encoding: Balluff system

- Drilling and milling drive: 37 kW (3,000 RPM)

- Angled milling head torque: 500 Nm

Torque on infinitely adjustable:

- Automatic swivelling

- Universal milling head: 1,500 Nm

- Motor grinding spindle: 11 kW, 6,000 RPM (adjustable speed)

- Additional features: Working area completely closed, workpiece and tool measurement, collision and tool breakage detection.

As part of SMS Holding GmbH, the SMS group is a group of international companies in machine and plant components manufacturing for the steel and non-ferrous metal industry. Over 14,000 employees worldwide help generate a turnover of approximately $37 billion. The manufacturer of large machinery, with locations in Mönchengladbach and Hilchenbach, produces all challenging machine and plant components for companies within the group in a closely integrated manufacturing and workshop network.

Starrag Group manufactures high-precision machine tools for milling, turning, boring and grinding workpieces of metallic, composite and ceramic materials. Principle customers are internationally active companies in the aerospace and energy, transportation and industrial components and precision engineering sectors. In addition to its portfolio of machine tools, Starrag Group provides integrated technology and maintenance services designed to enhance customer productivity. Starrag Group products are marketed under the following brands: Berthiez, Bumotec, Dörries, Droop+Rein, Scharmann, SIP, Starrag, TTL and WMW.

For more information contact:

SMS group

www.sms-group.com

Starrag USA Inc.

North American Headquarters

Skyport Business Park

2379 Progress Drive

Hebron, KY 41048

859-534-5201

ussales@starrag.com

www.starrag.com