Capto Toolholders Open New Range of Applications

May 1, 2020

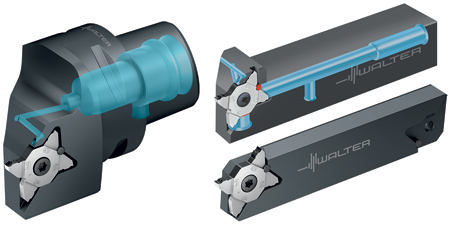

New Walter Capto toolholder and insert

Walter has added Walter Capto toolholders and insert widths to its Walter Cut MX grooving system. According to the company, Capto toolholders feature enhanced rigidity and modularity, while the tapered polygonal shape handles both torsional and bending forces with ease. This interface can be used for lathes and for turning/milling centers.

With the new Walter Capto monoblock tools (C3-C6), the MX system can now also be used on machines with Capto interfaces. In addition, new parting blades are introduced to work with automatic lathes and multi-spindle machines. Walter has completed the range with new grooving inserts and toolholders for larger insert widths. Where previously only 0.80 mm to a maximum of 3.25 mm were possible, the insert width now ranges up to 5.65 mm-including the common dimensions of 4 mm and 5 mm. Maximum cutting depth is 6 mm. These extensions are intended to make new applications possible for users of the MX grooving system, from small-parts production where a high degree of precision is needed to job shops where the focus is on fast, precise tool changes and cost efficiency.

The Walter Cut MX grooving system uses dowel pin location to prevent improper assembly of inserts into the holders. "The dowel pin location along with the horizontal seating surface also provides best-in-class positioning accuracy and diameter repeatability for the inserts, thus eliminating the need for test cuts after every cutting edge of insert change," said a company spokesperson. "With a unique design, the four-edge indexable inserts can be used even after one or more cutting edge breaks, for maximum cost efficiency. The inserts also have a very long tool life due to the Walter-specific precision cooling and the Tiger·tec Silver grades."

For more information contact:

Walter USA LLC

N22 W23977 RidgeView Pkwy West

Suite 100

Waukesha, WI 53188

800-945-5554

www.walter-tools.com/us

< back