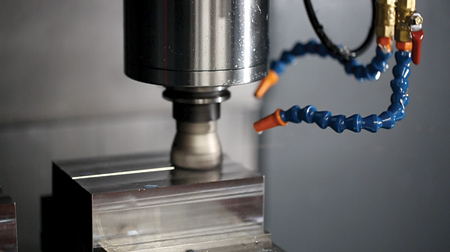

Hurco vertical CNC machines feature a one-piece double-column design that increases rigidity-enabling higher cutting feeds while maintaining part finish.

With the MAX 5 Hurco control, machinists can complete parts in one set-up through conversational programming.

Nearly all Hurco 3-axis machines are equipped with Hurco's UltiMotion technology, which simultaneously reduces cycle time and improves surface finish quality.

James McCloskey, President of Silver Tool, with the Hurco VMX42i.

Silver Tool, Inc. in Miamisburg, OH, specializes in machining fixtures, gauges, specialty machines, custom tooling and short run production. Founded in 1984 by Ed McCloskey, the company has grown from a small shop to a company with over 50 employees and 60 machines that are housed in a 30,000 sq. ft. facility. Ed's son, James, purchased the shop three years ago and now runs the day-to-day operations.

Ed McCloskey recognized that the only way to consistently manufacture quality parts, especially with the skills gap leaving shops short-handed, was to invest in technology. He took a financial leap of faith and purchased his first Hurco CNC mill in 2005.

Since that initial purchase, the company has added 12 more Hurco CNC machines to its fleet and it is still running that very first Hurco VM1 3-axis mill.

When Ed McCloskey first started looking at CNC machines, he knew he needed something that would make the transition from manual to CNC as easy as possible for his machinists. "Many of Silver Tool's employees at the time were used to running manual machines, but had not run CNC machines," he said. "With its intuitive conversational programming, Hurco was the answer."

The easy-to-learn conversational programming of the Hurco control has continued to be an advantage for Silver Tool as it navigates the skills gap. CNC machines with an easy learning curve are more important than ever with many shops struggling to find quality employees. James McCloskey, the current owner of Silver Tool, said that finding ways to reduce set-up time is the key to staying competitive.

"Set-up time is everything," said James McCloskey. "Set-up time might be half of the actual job itself; the Hurcos have low set-up times due to their ease of programming. Hurco control technology is user-friendly. We can take guys who have not run a CNC machine before and they can learn quickly because of the conversational programming."

While Silver Tool appreciates the benefits of conversational programming, the flexibility of the Hurco control to either program conversationally, NC or G-code with CAM software is the primary advantage. James explained that some jobs are better for conversational programming and some are better suited for NC. He finds NC/Conversational Merge, a Hurco control feature, extremely helpful because it allows them to combine the best of both conversational and NC into one program for maximum efficiency.

However, one of the newer Hurco control features called AdapiPath was a game changer for Silver Tool. "Watching how quickly material is removed is amazing. The adaptive tool path with the proper tooling has been a game changer as far as time savings," said James.

AdaptiPath is a conversational feature that uses the same technology found in high-end CAM systems to improve metal removal rates, reduce cycle time and extend tool life, according to Michael Cope, Product Technical Specialist at Hurco. AdaptiPath creates a smooth toolpath motion, controls chip load, provides constant tool engagement and also includes rest machining. "With rest machining, larger diameter tools can be used to efficiently remove material, followed by a rest machining pass that uses a smaller cutter to access the areas of the feature the larger tool could not access. Cycle time is significantly reduced due to the efficient material removal, especially for pocketing," explained Cope.

Because of Silver Tool's success with Hurco CNC machines, the company continues to grow and add more Hurco machines to its shop. It recently added its 13th Hurco CNC machine, a VMX42i, to go along with its Hurco machines: BMC 30 3-axis CNC mill; five VM1 3-axis mills; VM20 3-axis mill; VMX24 3-axis mill; VMX42i 3-axis machining center; HTM30i 3-axis toolroom mill; and two TM8 and TM10 CNC lathes. The VMX42i is considered the workhorse of the Hurco VMX Series with a 12,000 RPM spindle, a 50" x 24" table, travels of 42" x 24" x 24" and machine weight of 14,525 lbs.

"Hurco helps support our mission to produce quality workmanship while doing everything possible to please our customers," said James.

For more information contact:

Silver Tool, Inc.

2440 Crosspointe Dr.

Miamisburg, OH 45342

937-865-0067

www.silvertool.com

Hurco Companies, Inc.

One Technology Way

P.O. Box 68180

Indianapolis, IN 46268

800-634-2416

info@hurco.com

www.hurco.com