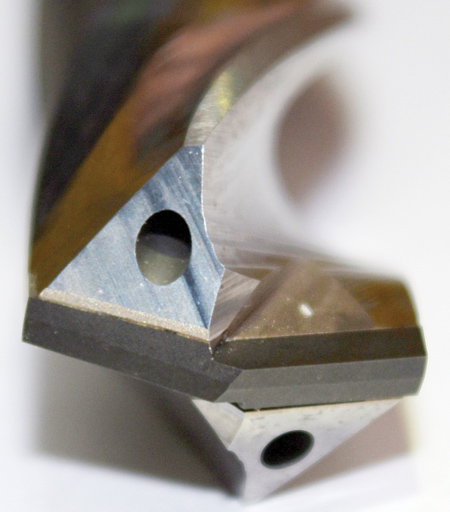

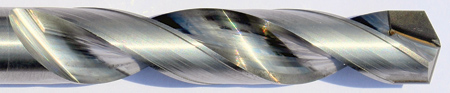

The EdgeX4-CCT-H, a helix version of the EdgeX4, features PCD across the full center for CFRP/composites and other abrasive materials.

EdgeX4-CCT-S, the straight version of the EdgeX4, features PCD across the full center for aluminum and other non-ferrous metals.

The full nib version, EdgeX4-FN, is suitable for CFRP/composites and can handle difficult geometries as well as smaller sizes.

An automotive transmission manufacturer wanted to increase tool life and lower cost per hole. West Ohio Tool Co. was already making carbide specials for this manufacturer's needs, but the company was looking into using polycrystalline diamond (PCD).

"When we were making their carbide drills, they were able to drill up to 225,000-250,000 holes per drill: 20,000 holes with a new tool, and then up to 10 additional regrinds also at 20,000 holes," said Kaci King, co-owner, West Ohio Tool Co. "The company was determined to move to PCD drills, so we began providing PCD outboard tipped drills. One drill was able to drill 350,000 holes, without regrind or retip, in the same diecast aluminum. We continued to innovate to see how we could make further improvements in tool life, as well as lower cost per hole."

"There is currently one additional manufacturer of a similar PCD drill," continued King. "However, its PCD is much softer and does not hold up as long, and it became our ultimate challenge to find a solution that could outlast that drill. We wanted our solution to be faster, stronger, longer and more efficient."

Innovation led to the EdgeX4, where the PCD lays across the whole center of the end of the drill, which took the manufacturer's tool life to 800,000-1,000,000 holes per drill-again without regrind or retip.

"When we can extend one drill's tool life from 225,000 to 1,000,000 holes, there is obviously significant cost savings per hole," said King. "When drilling with a PCD outboard tipped drill, the biggest problem was that the center of the drill was still carbide, which takes a beating and breaks down. When we extended the PCD across the center with a harder grade of PCD, it solved that problem as well, which dramatically increased tool life."

The EdgeX4 is working better than anticipated. "While it solved the customer's specific challenge-increased tool life and lower cost per hole-productivity also increased dramatically," said King. "Without having to stop the line to change tooling, less scrap is generated, so productivity goes up and costs go down. Surface finish remains excellent." To see a video of this case study, go to westohiotool.com/lowest-cost-per-hole-guaranteed.

The EdgeX4 drill is not just for aluminum manufacturers. "We also have these drills in several other facilities, including composite/carbon fiber reinforced polymer composites (CFRP) parts manufacturing and automotive brake manufacturers," said King. "The EdgeX4 is also drilling transaxle cases for small tractors and utility vehicles."

The EdgeX4 family includes:

- EdgeX4-CCT-H-Helix, or twist, version of the EdgeX4 with PCD across the full center for CFRP/composites and other abrasive materials.

- EdgeX4-CCT-S-Straight version of the EdgeX4 with PCD across the full center for aluminum and other non-ferrous metals.

- EdgeX4-FN-The full nib version is also suitable for CFRP/composites and can handle difficult geometries as well as smaller sizes.

West Ohio Tool Co. is co-owned by Kerry Buchenroth and his daughter, Kaci King, who has been with the business for more than 22 years. "We enjoy working with the end user to ensure they have the most effective tooling at their spindle," said King. "We determine possible tool combinations to streamline one process tool that shortens production cycle time and reduces customer tool inventory. Our engineers have 3D modeling understanding to create tooling from a part print. With our years of manufacturing, tooling, application and spindle knowledge, we are confident we can help other manufacturers gain the edge."

For more information contact:

West Ohio Tool Co.

P.O. Box 1457

7311 World Class Drive

Russells Point, OH 43348

937-842-6688

www.WestOhioTool.com

www.EdgeX4.com