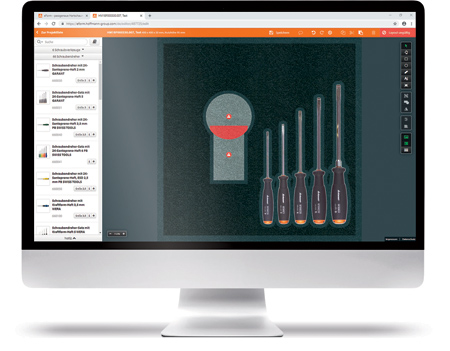

Using the eForm online configurator, Hoffmann Group USA customers can design rigid foam inlays where tools can be positioned above one another.

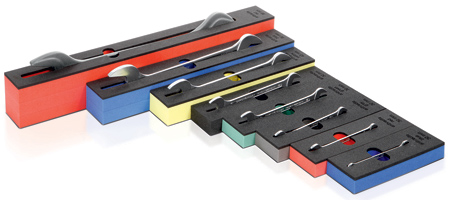

eForm rigid foam inlays are available in four thicknesses and six basic colors. New flame-retardant special foams are available in blue/black, and the conductive ESD foam is available in plain anthracite.

Hoffmann Group USA's web-based eForm configurator has been optimized for free-form surfaces. Using eForm, Hoffmann Group USA customers can design their own customized rigid foam inlays, whereby individually placed tools are not only positioned next to each other, but also above one another. This enables a larger number of tools to be stored in tool cases, drawers and cabinets in an orderly manner. A new XXL scanning pad, measuring 1,000 mm x 400 mm, makes it possible to create rigid foam inlays for small and extremely large tools-providing convenient storage options.

"With our newly optimized eForm configurator, creating customized rigid foam inlays for your drawers, cabinets and tool cases has never been easier," said Charlie Slagle, President and CEO of Hoffmann Group USA. "The end result for our customer is cleaner, easier to navigate storage systems and work spaces."

"The eForm rigid foam configurator from the Hoffmann Group USA makes creating rigid foam inlays for tool cases, drawers and cabinets simple: place the tools on the scanning pad; take a photo using a smartphone or digital camera, post-edit it on the computer and it is done," said a company spokesperson. Users can also configure their foam inlays on their computer, without the need for a scanning pad, by using the comprehensive database with 14,000 pre-installed tools and 30,000 tool contours from the field of machining and clamping.

With tool cases in particular, every millimeter of extra storage space is critical. That is why Hoffmann Group USA has expanded the eForm service with the "free-form surfaces" function. This enables a milling pocket to be created, for example, in which the blade of a file is positioned above the blade of a Gent's saw-creating a case that is better organized and that stores more tools.

For more information contact:

Hoffmann Group USA

202 N. Seven Oaks Drive

Knoxville, TN 37922

844-448-7725

sales.usa@hoffmann-group.com

www.hoffmann-group.com