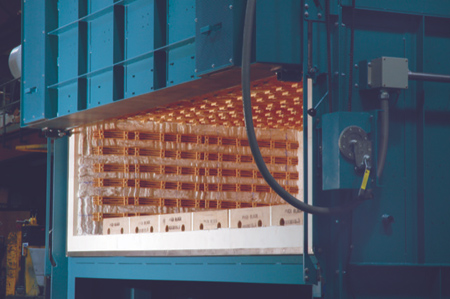

Large FB model box furnace for aerospace components.

L&L Special Furnace Co, Inc. has shipped a Model FB1046 floor-standing box furnace to a worldwide provider of high-tech aerospace and associated components located in the Southeastern U.S. The furnace will be used for processing aerospace parts and various thermal applications.

The work zone is 120" wide by 48" high by 72" deep. The furnace has a temperature gradient of ±20 °F from 1,100 °F to 2,150 °F using eight zones of temperature control with biasing to balance any differential in temperature gradients.

The furnace controller is a Eurotherm Nanodac program control/recorder that has 100 individual programs with up to 25 segments for each program. The furnace also has overtemperature protection with manual reset and backup safety contactors. There is a NEMA12 panel and fused disconnect.

The furnace has special slots that are cut into the door as a pass-through for atmosphere inlet and outlet tubes. This allows for inert atmosphere to flow directly into the customer's sealed parts manifold, and ensures good atmosphere circulation to the parts as they are being processed. The manifolds are supported on a series of castable piers located inside the furnace.

The furnace is rated for use to 2,200 °F and includes a 1,200 CFM venturi for accelerated cooling. There is an electric counterbalanced vertical door with a floor switch for activation.

All of L&L's furnaces can be configured with various options and be specifically tailored to meet customers' thermal needs. They may also be equipped with pyrometry packages to meet ASM2750E and soon-to-be-certified MedAccred guidelines.

Options include a variety of control and recorder configurations. A three-day, all-inclusive start-up service is offered with each system within the continental U.S. and Canada. International start-up and training is available by factory quote.

For more information contact:

Thomas Schultz, Sales Manager

L&L Special Furnace Co., Inc.

20 Kent Road / P.O. Box 2129

Aston, PA 19014

610-459-9216

tom@llfurnace.com

www.llfurnace.com