Simulation, Verification and Optimization Software to be Featured

May 1, 2017

The VERICUT logger now displays messages and reports from many sources. In addition to errors, warnings and other messages from the VERICUT session, it also displays information from AUTO-DIFF and X-Caliper.

The latest version of CGTech's CNC machine simulation software, VERICUT V8, will be featured in booth 5332. CGTech Sales Engineer Jeff Ulrich will give a presentation on Tuesday, May 16, 2017, from 11:15 to 11:50 AM. The presentation will highlight which feedrate optimization techniques are best suited for different materials or machining processes.

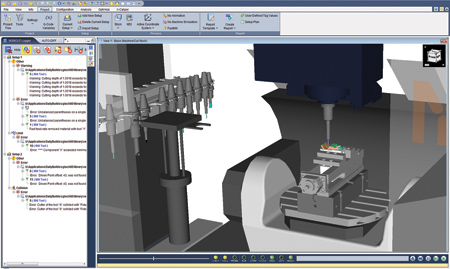

VERICUT CNC machine simulation, verification and optimization software simulates all types of CNC machining. It operates independently, but can also be integrated with leading CAM systems. A common feature of all recent releases of the software has been the focus on full integration with the CAD/CAM and machine tool industry. As a result, VERICUT is now at the heart of the CNC manufacturing process.

"This release is all about optimizing our customers' workflow to quickly access only the menu choices needed at the time," said VERICUT Product Manager Gene Granata. "The new Ribbon Bar helps users find the functionality they need quickly and with minimal mouse clicks."

VERICUT 8.0 features several enhancements designed to increase the ability of manufacturing engineers to analyze, optimize and document the CNC programming and machining process. Intelligence gathered from both the cut part and the machining process is applied to achieve an even higher level of accuracy and efficiency. CGTech is increasingly challenged to simulate more complex processes and machines, while supporting "first part, good part" production goals. VERICUT 8.0 ties complex processes together with the ability to monitor and evaluate many potential problems in an efficient and consolidated method, thereby reducing the time spent in the programming and machining cycle.

For more information contact:

CGTech

9000 Research Dr.

Irvine, CA 92618

949-753-1050

info@cgtech.com

www.cgtech.com

EASTEC Booth 5332

< back