Hanita's VariMill replaceable tip system, include a range of helix and cutting geometries, an asymmetrical flute design and wear-resistant AlTiN coatings for productive use in titanium and nickel-based superalloys.

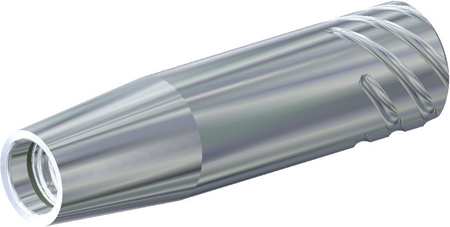

WIDIA offers a variety of integral shank taper, lobed and HSK-style toolholders, as well as straight shank "cut to size" adapters 10 - 32 mm (0.39 - 1.25") in diameter, all of which are available with Haimer Safe-Lock anti-pullout technology.

WIDIA offers a complete portfolio of precision-engineered products and custom solution services.

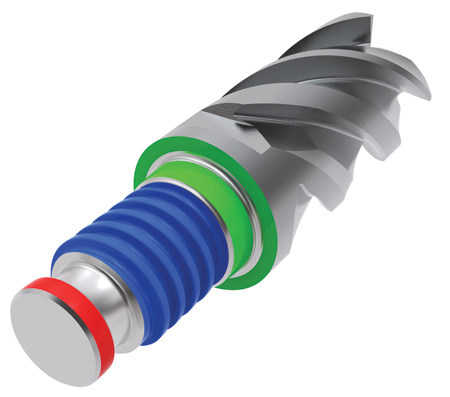

WIDIA's modular end mills feature a replaceable tip and the DUO-LOCK connection from WIDIA and Haimer. The end mill is engineered to take full-width slotting cuts in stainless steel and aerospace alloys at 1xD deep, and 50% cut widths at 1.5xD. "In cutting tests the DUO-LOCK connection was the only one that did not break," said Marketing Portfolio Director Avishay Zohar.

The metal removal rate is due to a double-taper, face-contact mount and intelligent thread design. This provides runout accuracy better than 5 µm (.0002 in.), axial repeatability of 10 µm (.0004 in.) or better and up to 25% higher torque and chip load capabilities.

Mark White, Marketing Portfolio Manager at WIDIA said, "The DUO-LOCK connection was originally designed for heavy roughing and semi-finishing applications in difficult materials, but the platform has evolved since then. When coupled with the wide array of carbide, coatings and geometries from our sister company Hanita, WIDIA provides manufacturers with a modular alternative to solid carbide end mills in 80% of its machining operations."

Examples include the WIDIA-Hanita brand VariMill III, a 7-flute center-cutting end mill with a 38° helix for high-feed machining of titanium and nickel-based superalloys, and the VariMill I, with a conical core and asymmetrical 4-flute design that eliminates chatter in extreme roughing and deep slotting applications. Both are available in WIDIA's Victory WS15PE and WP15PE AlTiN-coated grades.

All of WIDIA's modular cutting tools and adapters are available with Haimer's Safe-Lock technology, designed for zero pullout in titanium and other "grabby" materials.

For those shops that prefer a simpler toolholding approach, WIDIA offers a variety of integral shank taper, lobed and HSK-style toolholders, as well as straight shank "cut to size" adapters 10 - 32 mm (0.39 - 1.25") in diameter.

WIDIA is also offering a complete range of cutter geometries, from high-performance "corn cob" style roughers to ball-nose and chamfering cutters. Many of these are available in 20° and 45° helix angles, with custom grinds and edge preps possible in a few weeks or less.

"Our replaceable tip system decreases tooling inventory, machine downtime and operator headaches," said White. "A single toolholder or adapter accommodates any number of cutting heads. Unscrew one, thread on another, torque it down and you are ready to go, with no worries over tool runout or Z-axis offset changes."

For more information contact:

WIDIA Products Group

1600 Technology Way

Latrobe, PA 15650

888-979-4342 / 724-539-5000

na.techsupport@widia.com

www.widia.com