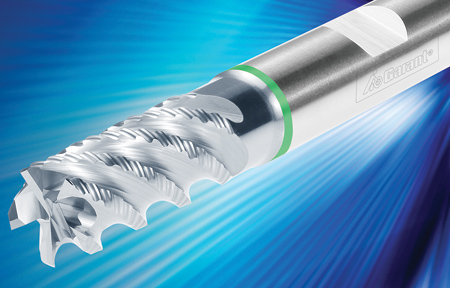

The new GARANT MasterSteel SlotMachine is suitable both for milling deep slots from solid and also for machining delicate components.

The new GARANT MasterSteel SlotMachine five-edge end mill is designed for higher process efficiency than a four-edge end mill. The knuckle form profile minimizes the cutting pressure putting less load on the component.

"The new GARANT MasterSteel SlotMachine from the Hoffmann Group is a solid carbide roughing end mill that achieves high feedrates when slot milling from solid in steel," said a company spokesperson. "The innovative knuckle form profile produces compact swarf. Therefore, the Hoffmann Group was able to construct the milling cutter with five cutting edges. As a result, at a constant feedrate per tooth, the new five-edge end mill achieves 25% higher process efficiency than a classic four-edge end mill," said the spokesperson. "Due to the innovative knuckle form profile, the cutting pressure is lower and higher feedrates can be obtained with a constant load. Due to the compact chips and the lower cutting forces, the new GARANT MasterSteel SlotMachine end mill is particularly suitable both for milling deep slots from solid and also for machining delicate components."

"Based on its unusual geometry, the new GARANT MasterSteel SlotMachine solid carbide end mill produces chips that are very short, very fine and particularly tightly rolled," said the spokesperson. "These are easily cleared by the flat chip-breaker recesses."

The GARANT MasterSteel SlotMachine permits plunge angles up to ten degrees. The cutting edge design includes honing to minimize the risk of breakaways. "The ultra-fine grain substrate greatly increases the resistance to breakage; while the enhanced coating also optimizes the wear characteristics and reduces the rate of heat input. The unequal spacing ensures a smooth cutting action," said the spokesperson.

The GARANT MasterSteel SlotMachine achieves a feedrate per tooth up to 0.1 mm at a cutting depth up to twice the tool diameter (2xD). It is available with cutter diameters from 4 to 20 mm.

The new GARANT MasterSteel SlotMachine solid carbide end mill extends the GARANT MasterSteel product range, which currently includes the existing classic four-edge end mills and also the GARANT MasterSteel PickPocket universal end mill plus two solid carbide drills.

For more information contact:

Hoffmann Quality Tools USA, Inc.

P.O. Box 30699

Knoxville, TN 37930

844-448-7725

sales.usa@hoffmann-group.com

www.hoffmann-group.com