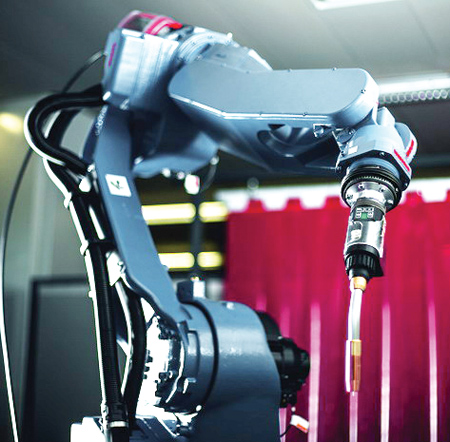

The Robacta Drive TPS/i push-pull robotic welding torch from Fronius features a compact design.

With the Robacta Drive TPS/i more welding tasks can now be performed cost-effectively by robots.

Due to the compact design and enhanced mechanics of the Robacta Drive TPS/i robotic welding torch, it has been possible to further improve component accessibility and TCP precision.

Fronius has introduced a small push-pull robotic welding torch, the Robacta Drive TPS/i. Due to its compact design and enhanced mechanics, the component accessibility and TCP precision of the torch have been further increased and the dynamics of the drive unit have been increased tenfold compared to the previous generation, to 33 m/s2. The consistent modular structure also makes handling easier during servicing, and simplifies the storage of stock and spare parts.

The optionally gas or water-cooled welding torch can, with its small interference contour and reduced weight, be used with robots with a load capacity of just 3 kg. Despite its small dimensions, the lightweight device has a powerful three-phase step motor for smooth movement of wires at speeds of up to 25 m/min. The speed is kept constant by an integrated positional encoder. Two driven feed rollers transfer the speed to the wire electrode. When replacing the entire system, the TCP accuracy of 0.5 mm is guaranteed.

The Fronius engineers have given the new torch a consistently modular design: The hosepack and drive unit in the Robacta Drive TPS/i are coupled via a standardized connection using a union nut. As the connection to the welding current source is also made via a quick-release lock (FSC), which includes all required media and signal cables, the hosepack can also be replaced quickly. Due to the modular design, the same drive unit can also be used for robot types with external hosepack, as well as with hosepacks that are routed inside the robot's arm.

Even greater availability is facilitated by sophisticated details, such as the simple setting of the contact pressure, aided by a display and using a tool-free adjustment screw, or the ergonomic user interface. The latter features a dot-matrix display and pre-assigned keys for wire feeding and the gas test, as well as a freely programmable function key.

For more information contact:

Fronius USA LLC

6797 Fronius Drive

Portage, IN 46368

219-734-5701 / 877-FRONIUS

sales.usa@fronius.com

www.fronius.com