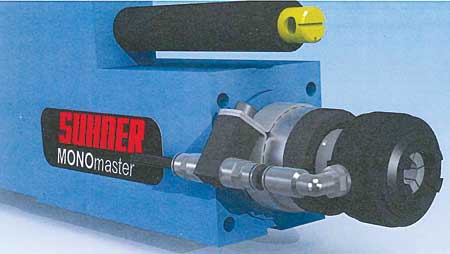

SUHNER automated quill-feed drilling units equipped with the REGO-FIX reCool system feature new through-tool-coolant capabilities.

The REGO-FIX reCool system now provides the benefits of through-tool-coolant capability to users of SUHNER automated quill-feed drilling units. According to a spokesperson, SUHNER's Automation Division, a longtime REGO-FIX distributor in the Southeast and manufacturing company, collaborated with REGO-FIX to offer such capability where it was previously unavailable or impossible to achieve in a cost-effective manner.

"REGO-FIX's innovative reCool system is an alternative to expensive, high maintenance through-coolant-dedicated live tooling heads," said the spokesperson. "With just four components - a special clamping nut with outer ring, coolant pipe, straight fitting and elbow fitting - the system retrofits onto existing live tooling heads with an ER output (straight and angled) in approximately two minutes. With reCool, shops can quickly, easily and cost effectively transform the standard external-coolant live tooling heads into those with through-tool-coolant capability.

"SUHNER now offers them the option of quill-feed systems equipped with reCool. Choosing through-tool-coolant capability on such systems increases tool life, more efficiently controls chips and reduces heat generation for faster speeds and feeds, thus resulting in shortened cycle times and increased productivity."

"We targeted our quill-feed units, in particular, because the internal designs of the systems prohibited traditional through-the-spindle coolant delivery," said Lee Coleman, Manager of SUHNER's Automation Division in North America. "reCool is maintenance-free and allows us to offer our customers an easy and affordable method for systems frequently used in extremely high-volume production environments to have through-tool coolant capability."

SUHNER's Automation Division provides machining units for drilling, milling and tapping operations. The company exclusively quotes tooling products from REGO-FIX to its customers and serves as a complete supplier of holders, collets and collet nuts.

For more information contact:

Bill Obras, VP, Sales & Marketing

David McHenry, Sr. Product Engineer

REGO-FIX Tool Corp.

7752 Moller Rd.

Indianapolis, IN 46268

800-REGO-FIX (800-734-6349)

info@rego-fix.com

www.rego-fix.com