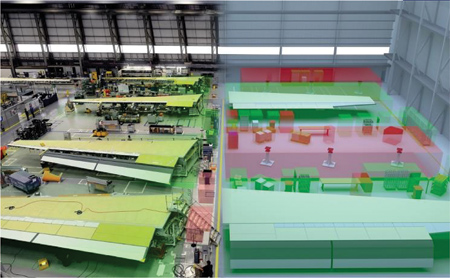

Ubisense's IIoT platform SmartSpace creates a digital twin of aerospace manufacturing facilities

Lockheed Martin Aeronautics has licensed Ubisense SmartSpace for deployment at its F-35 program at Fort Worth, TX, to improve manufacturing efficiency.

Richard Petti, CEO at Ubisense, said, "We are delighted that our SmartSpace digital manufacturing platform is now being deployed across the Fort Worth site to provide complete visibility of the manufacturing process, unlocking the power of location to deliver a real-time view of operations. Ubisense has worked in the aerospace sector for many years, helping companies to drive productivity and reduce costs and we look forward to our partnership with Lockheed Martin delivering significant value to the F-35 program."

Ubisense SmartSpace is designed to change the way aerospace manufacturers deliver aircraft on time and to budget, providing complete visibility of the manufacturing process by integrating location technologies into a single operational view of production. For Airbus, Ubisense provides an `indoor radar', connecting with SAP to ensure timely arrival of components for assembly and up-to-date information management.

"SmartSpace can solve a number of challenges faced by manufacturers with long cycle times and high complexity such as those in aerospace, defense and commercial vehicles," said a Ubisense spokesperson. For these customers sites are often vast, making it easy to lose sight of tools and assets. However, if these critical items are not in the right place at the right time it can cause lengthy and very expensive production delays. By understanding the precise location of tagged assets in real-time, as well as where they need to be at specific points in the future, SmartSpace enables the proactive staging and scheduling of assets to help meet critical milestones. The platform not only tells where assets are but provides a level of control to ensure that uncontrolled or incorrect tools are not used in specified workspaces.

Ubisense's platform also offers electronic audits of assets and tools, detailing the whereabouts of all customer Furnished Equipment, enabling manufacturers to respond to spot checks quickly and efficiently and avoiding fines for failure to do so. Problems in the manufacturing and delivery of component parts can mean delays in final assembly and missed delivery dates, which can lead to hefty fines. By tracking the progress of parts across sub-assembly lines, at multiple plants, SmartSpace enables manufacturers to proactively plan final assembly based on delivery delays.

"Delivering new levels of visibility and control, SmartSpace provides a foundation platform for manufacturers' Industry 4.0 strategy," added the spokesperson. Creating a real-time digital twin of the production environment, Ubisense's technology connects activities in the real world to manufacturing execution and planning systems, making real-world processes involving moving assets visible and measurable.

For more information contact:

Ubisense Group Ltd.

https://ubisense.net/en/products/SmartSpace