Configurable M50 MILLTURN

January 1, 2025

M50 MILLTURN

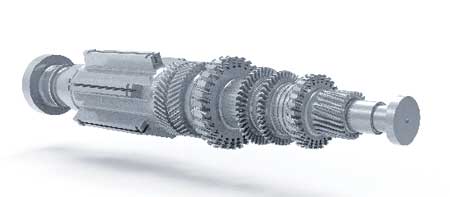

Power generation shaft is machined on an M50 MILLTURN/3,000 mm.

Live machining on a power generation shaft.

The M50 MILLTURN-the "WFL power pack"-has been introduced by WFL Millturn.

"The M50 MILLTURN with 4,500 mm center distance has its advantages in a wide range of tools that can be used in powerful drives, in the rigid connection of prismatic tools on the B-axis, in good ergonomics at the operator station and in various tools and cycles implemented on the control panel to increase productivity and process reliability," said a company spokesperson. "The customer can configure a machine using many available technology modules. The corresponding WFL cycles on the control support the customer in generating a productive workflow."

With the M50 MILLTURN, special attention has been paid to a user-friendly access to the standard tool magazine, which is accessible from the front via the generously dimensioned viewing windows. Moreover, the large viewing windows in the sliding doors allow for an overview of the working area. Especially bright LED lamps, which are similar to daylight, are installed within the working area of the basic machine as standard. There is a separate pick-up magazine for very long and/or heavy tools. Workpieces with a length up to 1,600 mm can be used and changed automatically. Even though the disc magazine can be enhanced up to 200 stations recently, all tool stations can be accessed directly. Furthermore, reliable optical sensors are installed within the tool magazine for monitoring the tool stations.

"WFL continuously optimizes the machining processes in its machines," said a company spokesperson. "However, there are always interruptions requiring operator intervention, such as measurements and controls. It is important to minimize these interruptions to make best use of the availability and productivity of the machine. This is ensured by software packages in the machine control as well as additional intelligent clamping devices and tools automating the processes."

For more information contact:

WFL Millturn Technologies

Autania Tec Center

48152 West Road

Wixom, MI 48393

248-347-9390

office@wfl-usa.com

www.wfl-usa.com

< back