The Bumotec 191neo is not just one machining solution, but essentially 12 different machines on a single platform.

The Bumotec 191neo, with its large glass panes and optimally positioned access doors, offers a good view of the different areas of the machine and improved access for operators.

The "PRM" configuration of the Bumotec S191neo enables the production of two pieces in one cycle.

4: Medtech: dual bone plate

Material: 304 stainless steel

Bar diameter: 1.65" inch (42 mm)

Cycle time: 25 minutes (per plate)

The Starrag Bumotec s191 turn-mill center offers high flexibility and a new HMI makes operation easy.

According to Starrag, customer requirements of all kinds can be met due to the modular design: different peripheral devices, such as temperature-controlled high-pressure systems, chip conveyors and bar loaders, are available. Users can machine numerous complex and demanding workpieces in a single set-up because the Bumotec 191neo can not only turn, mill, grind and polish, but can also handle less frequent machining operations, such as gear hobbing, engine turning and diamond cutting.

The Bumotec 191neo features large glass panes and optimally positioned access doors, offering a good view of the various areas of the machine and improved access for operators. A light strip provides information about the operating status at a glance. With the ergonomic design, staff can switch between screens with a simple finger movement. The progress of ongoing machining operations, the configuration of programming or the monitoring of production can be tracked in real time.

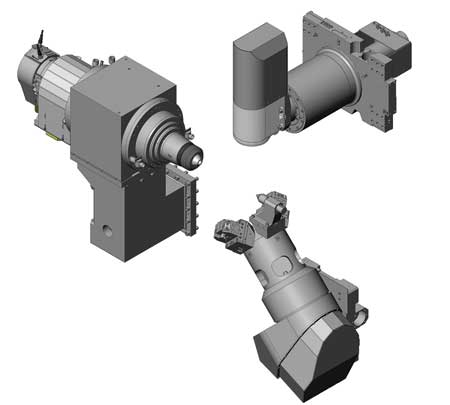

Starrag supplies the machining center in versions with vise "P," multiple vise "PRM," counter spindle "R" and counter spindle/vise combination "RP" with a bar capacity of 42 mm, 50 mm or 65 mm.

"The Bumotec 191neo is not just one machining solution, but 12 different machines on a single platform," said a company spokesperson. "It is only with this variety that the special requirements of typical users from medical technology, the luxury goods industry and micromechanics can be optimally fulfilled both from an economical and a technological perspective.

The Bumotec 191neo features enhanced stability, reliability and productivity even without user intervention, the company reported. Due to the reduction in tool change time by about 15%, it meets high cycle time requirements and reduces unproductive downtime. The increased torque of the Starrag milling spindle and the electric motor-controlled pick-up unit, which is 12% faster than before, offer improved productivity.

The Bumotec tool magazine with over 90 tool places as standard has a broken tool sensor working in parallel. When used in combination with a Bumotec palletizer or a robotic automation cell, continuous production around the clock can be achieved that only needs to stop for preventative maintenance.

For more information contact:

Starrag USA Inc.

Skyport Business Park

2379 Progress Drive

Hebron, KY 41048

859-534-5201

ussales@starrag.com

www.starrag.com