LoadMate Plus is an engineered robotic solution that can be used for machine tending, with an RV20, 6-axis robot arm.

LoadMate Plus offers flexible connectivity for plug & play machine tending. There is no need for robot expertise. For communication, all that is required is a simple connection via Ethernet to integrate the LoadMate Plus with Mitsubishi Electric's M8 Series CNC.

To help ensure precise placement of the part to be machined, the robot arm works with a flexible Schunk quick-change pallet system.

It only takes 15 minutes to place 10 blanks on the loading shelves. From there, the system automatically loads and unloads the machine.

Le had been working with Expand Machinery for several years, using a wide range of Expand milling machines, most of which use controls made by Mitsubishi Electric Automation.

TL Aerotek has a reputation for providing precision components for large aerospace companies. This small-job shop has been in business for five years and has continued to grow, requiring the company to move from its original 600 sq. ft. space to a new shop with seven machine tools in over 2,000 sq. ft.

Clearly, business has been good, with orders flowing in faster than owner, Tai Le, could fill them. He wanted to keep up with accelerating demand and continue building his business, but did not want to deal with labor uncertainty.

Looking for a solution, Le consulted long-time supplier, Expand Machinery, a family-owned business that specializes in building machine tool systems with emphasis on building relationships.

Expanding with Expand Machinery

Le had been working with Expand Machinery for several years, using a wide range of Expand milling machines, most of which use controls made by Mitsubishi Electric Automation.

Over the years, Le has slowly replaced all other machine brands with Expand and Mitsubishi Electric products, saying, "Both companies give me what I need: super support, performance and reliability."

LoadMate PlusT

After working closely with Le, Expand's General Manager, Ravjeet Singh, suggested automating the process of loading and unloading machines using the LoadMate Plus system from Mitsubishi Electric Automation.

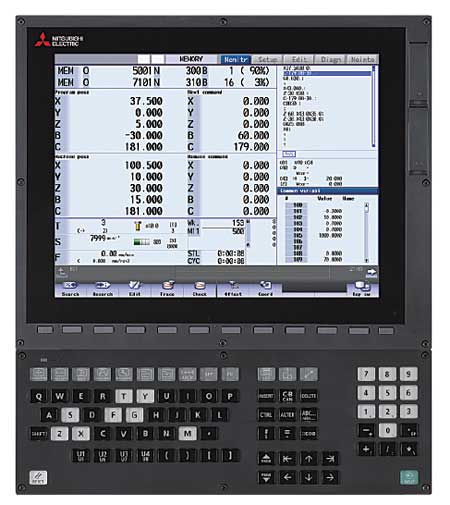

LoadMate Plus is an engineered robotic solution that can be used for machine tending. Expand developed and integrated a 4' x 4' LoadMate Plus with an RV20, 6-axis robot arm. It was easily connected to one of Le's machine tools, the GenMill 5X-12. Because this 5-axis milling system was already equipped with a Mitsubishi Electric CNC, getting everything to communicate was easy.

According to David Contreras, Mitsubishi Electric Account Manager, "The LoadMate Plus has been specifically created for easy set-up and use."

Plug & Play Machine Tending

In short, the LoadMate Plus offers flexible connectivity for plug & play machine tending. For communication, all that is required is a simple connection via Ethernet to integrate the LoadMate Plus with Mitsubishi Electric's M8 Series CNC.

In addition, the system offers easy programming of the robot movements due to direct robot control with CNC software. That means Le could program and adjust on the fly using menus and G-code from the same screen used for the machine tool. There is no need for robot expertise.

To help ensure precise placement of the part to be milled, the robot arm works with a flexible Schunk quick-change pallet system. Singh said, "Working with Tai, we chose to focus on a pallet system that allows the robot to pick up parts from the same location each time so you do not have to reprogram the robot from part to part. We chose to use Schunk for our pallet system needs because of its well-known rigidity, accuracy and durability."

"I like to be self-sufficient," said Le. "Because my machines are supported by Expand and Mitsubishi Electric, I know that if I do need help, I will have it. However, because the machines and controls are so good, I do not think I will need that help too often."

Automatic Loading/Unloading Triples Output

It only takes 15 minutes to place 10 blanks on the loading shelves. From there, the system automatically loads and unloads the machine. That means Le no longer has to stand by to remove a finished part and load new material. The LoadMate Plus does it all and will keep doing it until the loading shelf is empty. In fact, after implementation at TL Aerotek, the system ran unattended for 24 hours, tripling normal output. Le is now able to complete a month's quota in just a week.

Le was pleased with his new level of productivity. As a result, he ordered two new 5-axis machines to replace two of his 4-axis units. These two new machines will be facing each other. In between them will be a new LoadMate Plus. Its robot arm will have a longer reach, making it possible to load both new milling machines with one LoadMate Plus.

"Tai Le is a great example to other small outfits," said Singh. "He knows that if you do not invest, you cannot grow your business."

For more information contact:

Mitsubishi Electric Automation, Inc.

500 Corporate Woods Pkwy.

Vernon Hills, IL 60061

847-478-2100

us.mitsubishielectric.com/fa/en

Expand Machinery LLC

20869 Plummer St.

Chatsworth, CA 91311

888-542-6374 / 818-349-9166

sales@expandmachinery.com

www.expandmachinery.com