Automation enabled Ultradent to triple throughput and gain market share.

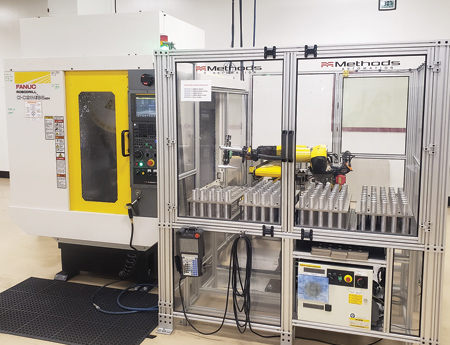

RoboDrill custom turnkey automation cell engineered by Methods

Meeting demand in a consistent, cost-effective manner requires balance and good forecasting. But sometimes it takes a little more due diligence to uncover the best way to increase throughput or meet rising demand.

Ultradent Products, Inc., a developer and manufacturer of high-tech dental materials and devices for the medical industry, faced such a problem. The company sought to increase the production of its industry-leading Valo curing light, used by dental clinicians to cure dental composites, sealants and various other chemistries.

Ultradent's Valo curing lights are complex pieces of equipment, requiring numerous holes, finishes and different geometries. In 2017, Ultradent required almost 50 minutes and three complex machining operations to produce one curing light housing.

Ultradent's original manufacturing process involved hand-loading raw materials and finished parts; a cumbersome and sluggish process for a company that only had three employees on the shop floor per shift. The manufacturing set-up resulted in the occasional spindle crash, hindering operations and output.

"We needed more reliability and faster cycle times," said Ryan Umpleby, Senior CAD/CAM Programmer at Ultradent.

Moreover, the company occasionally had to subcontract work to meet rising demand. Not only was that an additional cost, but Ultradent also had to perform additional operations to remove imperfections left by the subcontractor.

"We never end up fully outsourcing the part because their costs are too high, or they cannot match our quality," Umpleby added.

Ultradent needed to reduce the part's cycle time while simultaneously increasing repeatability.

After engaging Methods Machine with the project requirements, Ultradent moved forward with two custom automation cells, each comprising an advanced FANUC RoboDrill, a FANUC robotic arm and raw stock storage. Methods designed the system to hold 60 blanks-uniform pieces of raw material ready for machining.

At first, implementing a custom automation cell was a hard sell. Not everyone at Ultradent believed a smaller machine could outperform a larger horizontal machining center, one of the other options the company was considering.

"This small RoboDrill with a robot arm was a little intimidating," Umpleby said. "It is smaller than a horizontal, it is automated and it has a robot."

"Anytime you introduce something new, people can be hesitant," added Kevin Marett, an Engineering Manager at Ultradent.

Umpleby accessed Methods' vast support network, comprising application engineering, automation integration and installation experts. With the support team providing backup and guidance on demand, Umpleby got the cell up and running.

The automation cell provided actionable data points, delivered precise results and cut the cycle time for a curing light housing in half-from about 45 minutes, down to a 21-minute average. With only three employees on the shop floor per shift, automating the cumbersome process of loading/unloading material significantly improved Ultradent's workflow.

With 24/7 operations underway, Ultradent increased its throughput almost threefold while also reducing machining costs associated with third-party processing.

"With the help from everybody at Methods, we were able to pull together and come up with fast solutions," Umpleby said.

While the second RoboDrill automation cell was getting the job done on-time and under-budget, Ultradent needed to expand the system. So, the company adopted a larger, third cell that boosted the blank capacity from 60 to 200.

After executing the idea, the company automated an entire production run of 200 curing light housings.

"That was a pretty cool milestone for me, to see Methods pull through that quickly on such a huge change to the cell," Umpleby added.

Soon after, Methods added a fourth 200-capacity automation cell, bringing the total to four RoboDrills and four robotic components.

The RoboDrill cells run unattended for 16 hours a day and completely lights-out on the weekends. In addition to increased throughput and machine uptime, Ultradent has gained the desired repeatability due to the RoboDrill's rigid construction and precision.

Since implementing the RoboDrill and automation cell, Ultradent's quality assurance team has noticed a significant improvement in the machining accuracy of the curing light housing with perfectly threaded, 12 mm blind holes.

"The fact that the RoboDrill repeats on the threading and other features is pretty important to us," Marett said. "As we go through inspection data for thousands of units, we find that features do not move within a half a thousandth of an inch. Part of that is tooling, part of that is how the tooling is held and how the machine is built so it will repeat from position to position."

"Ultradent did more than just increase throughput machine uptime and improve repeatability-they captured more market share," added a spokesperson.

For more information contact:

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

877-MMT-4CNC (877-668-4262)

www.methodsmachine.com

Ultradent Products, Inc.

505 West Ultradent Drive

South Jordan, UT 84095

888-230-1420

www.ultradent.com