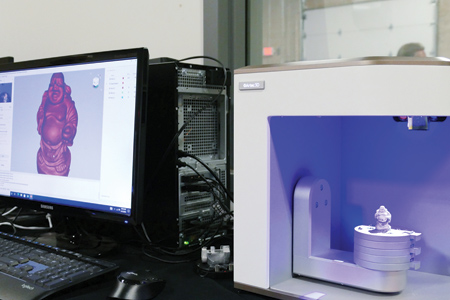

Scan used for reverse engineering.

Attendees were able to see many equipment lines demonstrated and interact with Exact technicians.

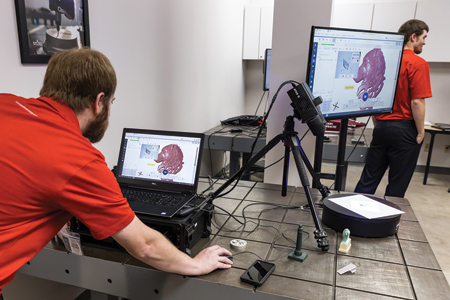

Artec Blue Light scanner in action.

3D scanning

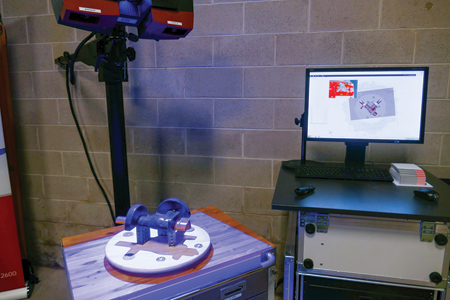

Surface inspection demonstrated using a Hexagon Romer Arm.

Exact partner PolyWorks demonstration of software data collection.

CMM measuring a suspension section.

Exact technician performs a scan.

Ward Tannhauser demonstrates Artec Blue Light scanner

Breakout sessions drew standing-room-only crowds

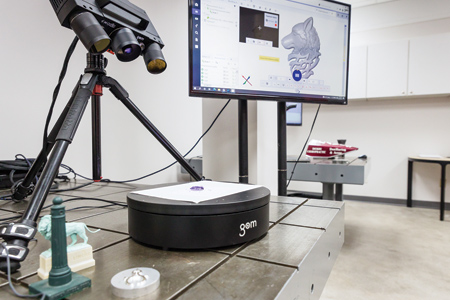

GOM CT scanner in action

A breakout session gave attendees an array of scanning and data collection tips.

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, recently hosted technology fairs at its facilities in Brookfield, WI, and Moline, IL.

Each event drew over 100 people from the surrounding areas who were interested in learning more about the industrial benefits of innovative and highly accurate 3D scanning technologies and software. Attendees included quality assurance and quality control engineers, manufacturing and production personnel and other supervisors and technicians from a variety of industries, including power generation, automotive, off-highway, consumer durables and others.

Dimensional metrology instruments displayed included the latest scanners from Artec, Hexagon Manufacturing Intelligence, GOM CT, Romer and more. In addition, demonstrations were provided showing the advanced functions of PolyWorks and Geomagic 3D software.

At the Moline facility, attendees witnessed the precision measuring and dimensional layout capabilities of that location's in-house large-scale coordinate measuring machine (CMM). The technology fairs in both locations featured hands-on scanning and data capture demonstrations as well as educational training sessions in breakout rooms. Discussions were led by Dean Solberg, Vice President, Greg Goth, Division Manager, technology partner personnel and other Exact Metrology engineers.

Among the topics discussed by attendees during the luncheon and demonstrations were technology trends, including robotics, the benefits of reverse engineering parts and components, and long-range scanning of complete process lines and equipment.

For more information contact:

Dean Solberg

Exact Metrology

Div. of In-Place Machining Co.

20515 Industry Avenue

Brookfield, WI 53045

262-533-0800 / 866-722-2600

deans@exactmetrolgy.com

www.exactmetrology.com

Exact Metrology

Div. of In-Place Machining Co.

4715 15th St. A

Moline, IL 61265

309-524-4323

www.exactmetrology.com