Large scale automated quality control in a factory often involves closed-loop feedback of offsets to production machinery to ensure components are always within tolerance and that process capability is maintained. A web-based portal is invaluable for management and engineers to monitor such activities from anywhere in the world.

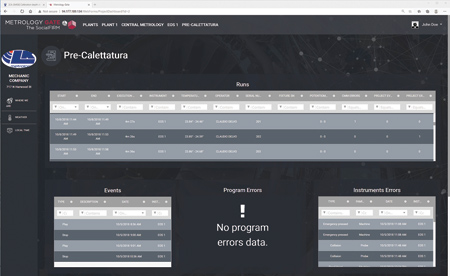

CMM status monitoring, program runtime information, utilization, etc. on a web-based platform. Such quality performance data can be accessed worldwide on any internet-connected device. The Metrology Gate software is particularly useful for monitoring automated inspection cells or environments where multiple CMMs are running and not being monitored full time by a dedicated operator. The CMM information gathered can also help in determining the life span of the probing, time between preventive maintenance, etc.

Aimed at multinational organizations with factories worldwide but equally applicable to medium size companies having several production facilities in one country, a web-based platform is available from coordinate measuring machine (CMM) manufacturer LK Metrology to help production departments monitor and control inspection activities around the clock.

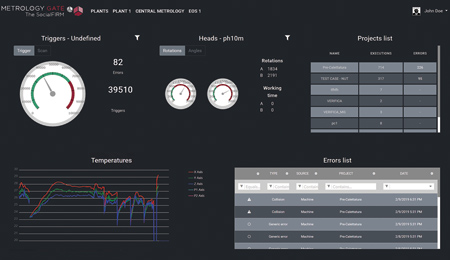

Consistent with the aims of Industry 4.0, the Metrology Gate portal provides remote access to information on the status and performance of all connected metrology devices. Information available includes measurement results and a summary of errors, a record of program changes, uptime of the CMMs and overall equipment effectiveness (OEE). Historical logs assist with troubleshooting and warn when routine maintenance is due, not only of the inspection machines but also of the machine tools or other equipment on which the components are being made.

Delays in data searching are avoided, improving reporting procedures. Comprehensive daily reports include total output per shift and the number of parts measured, sudden changes in process averages and comparisons between different machines producing the components. Graphical CAD reports, statistical process control (SPC) analyses with Cp and Cpk results and environmental logs including operating temperature are generated and communicated, alongside charts to aid interpretation and understanding.

In the case of critical dimensional discrepancies or hardware failure, the software shares the information with users immediately by sending alerts via email, SMS, WeChat or WhatsApp. Metrology jobs can be stopped and reset if performance is inadequate, maximizing yield and minimizing scrap. A dashboard containing details of the errors may be viewed on a web page.

Normally, data acquired is stored in the cloud, but may be held on servers in different countries if preferred, or even on an individual computer. It is accessible over the internet instantly and globally in real time, on a PC in an office or using an app on handheld devices when on the move.

"Because the quality control data is acquired automatically and therefore objectively, its accuracy is practically guaranteed," said a company spokesperson. "The risk of human error is avoided, including during the preparation of reports, which are produced automatically rather than laboriously by hand, and are easily tailored to suit what the customer needs to see."

A hierarchical permissions structure can be built into the platform so that personnel have access only to information relevant to their seniority and requirements. The system can be phased in by implementing it in one factory and gradually expanding the network with additional licenses.

For more information contact:

LK Metrology, Inc.

29550 W.K. Smith Drive, Unit B

New Hudson, MI 48165

810-263-6100

sales.us@lkmetrology.com

www.lkmetrology.com