Solution Increases Die Cast Turning Productivity

January 1, 2022

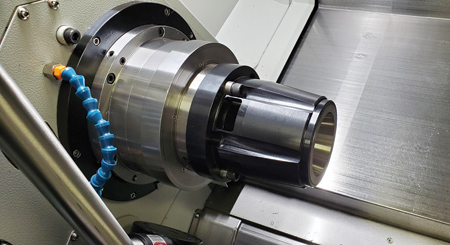

Zagar 22c CNC collet chucks and collets offers quick-change and secure holding of die cast parts for turning operations

Zagar Inc. has increased its design and engineering services for customers seeking custom workholding for lathe operations. Zagar 22c CNC collet chucks are offered along with standard collets that are modified to mate exactly with unique die cast part configurations. These parts can be held securely on either I.D. or O.D. surfaces, providing increased machining access.

One CNC collet chuck holds each modified collet. Working together with a draw-bar spindle and coupling with the back of the collet chuck, the clamp mechanism is actuated inside to securely locate and hold the part in a single step. The set-up helps to ensure machining performance while providing low runout as well as quick changeover to keep machine uptime high.

CNC collet chucks and collets are an alternative to pneumatic or hydraulic workholding devices and are suited for high production runs. According to the company, standard shapes such as round, square and hexes can be held accurately and quickly compared to a three or four jaw chuck.

For more information contact:

Zagar Inc.

24000 Lakeland Boulevard

Cleveland, OH 44132

216-731-0500

sales@zagarinc.com

www.zagar.com

< back