MMV 4200

MMV 6200

60-pocket tool magazine MMV 5200

MMV 3200CNC milling center

Working area with movable control panel

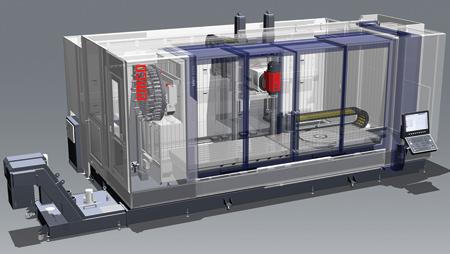

With the MMV 4200 / 5200 / 6200 models, EMCO offers an extension to its MMV series. They feature increased travel paths (X= 4200 / 5200 / 6200) in response to increased demand in the traveling column machine segment.

The machines with 3, 4 and 5 axes can be used for complete machining of very large and heavy parts in one clamping. The technology of the MMV 3200 has been kept in the new models: a high-performance motor spindle with 0-15,000 RPM speed range, 46 kW spindle power and up to 170 Nm torque. Forty tool pockets are standard, and optionally expandable up to 120 pockets.

"Due to the new modular system, customers do not have to choose between a smaller machine or one that is too large; variable sizes are possible up to 6,200 mm," said a company spokesperson. "The main difference between the MMV 4200 / 5200 and 6200 and the previous model is the X-axis drive, which uses a rack & pinion system instead of ball screws. This ensures dynamic, fast and precise feed during machining. The demand for these high-performance machines comes mainly from the petroleum industry, railroad industry and intralogistics."

The compact machine bed of the traveling column machining centers is a heat-treated, welded steel structure that provides a torsion-resistant and stable base for all components and machining operations. The production of large and heavy workpieces up to 8,000 kg is enabled by a motor spindle with 46 kW spindle power, torque of up to 170 Nm and spindle speeds of up to 15,000 RPM (18,000 RPM HSK-A63). Both spindle versions are grease-lubricated.

The new versions of the previous model support complete machining of long and heavy workpieces without reclamping. A new modular system allows a variable choice of workpiece sizes up to 6,200 mm during machining. The large work area doors allow easy loading and unloading of workpieces and fixtures, even when using a crane.

As standard, the machines have 40 stationary tool pockets; these can be increased to up to 120 tool pockets (also optionally alongside column) on request. The MMV 4200/5200 and 6200 feature a rack & pinion X-axis drive system that is designed to provide dynamic, fast and precise machining at all times, even with long travels.

With this system, rapid traverses of up to 60 m/min can be achieved.

The machine versions with swivel head (B-axis) and rotary table (C-axis) are suited for 5-axis simultaneous machining. Both the swivel head and the rotary table are driven by dynamic torque motors. The swivel head available in the standard versions has a range of up to ± 120° and a speed of 50 RPM, and the rotary table n x 360° has a speed of up to 100 RPM. The rotary table with O 900 mm is designed for workpiece weights up to 2,000 kg. All linear axes are already equipped with glass scales as standard. The dynamic linear axes and the torque drives of the rotary axis create ideal conditions for 5-axis simultaneous machining of complex workpieces.

Digital control systems from Heidenhain (TNC 640 - 24" monitor) or Siemens (840D sl - 22" monitor) provide user-friendly machine operation. The ergonomic design of the MMV series with its movable control panel creates ideal working conditions for the operator, who can swivel and rotate the control panel in the working area, as well as move it along the longitudinal axis without interrupting the machining process, while keeping the workpiece in view at all times.

The machining centers can be equipped with numerous options, such as coolant filtering systems with high pressure pumps with up to 60 bar through the spindle, which permit the use of high-performance tools with internal cooling. All guides and rack drives are permanently grease-lubricated via a central lubrication system, while oil films are kept from forming in the coolant system.

Touch probes allow automatic measurement of tools and workpieces. RF or laser touch probes are optionally available. This reduces the set-up time for tool changes and increases the quality of the workpiece.

Due to the large working areas of the MMV series machines, it is possible to optionally add a partition wall for pendulum operation, a second integrated rotary table or and NC axis with counter bearing.

Features such as the automatic door operation or thermal compensation of the milling spindle provide more efficiency.

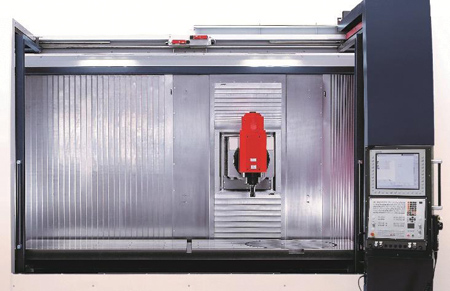

MMV 3200

The MMV 3200 is available in 3- or 4-axis versions with a B-axis. For 5-axis simultaneous machining, an integrated torque rotary table is added as a 5th axis. With the option of adding a second torque rotary table, 5-axis machining can be performed in pendulum mode in two workspaces.

In addition to the stationary tool magazine with 40 pockets (optionally up to 60 pockets) on the left side of the machine, a further 60 tool pockets can also be installed on the right. Alternatively, for 4- and 5-axis machines, tool magazines with 40, 60 or 120 pockets can be mounted on the traveling column. The machine also features a high-performance motor spindle with a speed range of 0-15,000 RPM, an output of 46 kW and a torque of up to 170 Nm. "These features make the MMV 3200 the ideal machining center for high-quality milling and enable the complete production of complex workpieces with excellent surfaces. The machine is equally suited to the requirements of the automotive or aerospace industry, as well as to those of machine manufacturers or job shops," said the spokesperson.

The compact machine bed of the moving column machining center is a heat-treated, welded steel structure that provides a torsion-resistant and stable base. The production of large and heavy workpieces up to 5,000 kg is possible with a powerful motor spindle with 46 kW spindle power, a torque of up to 170 Nm and a spindle speed of up to 15,000 RPM (18,000 RPM HSK-A63).

For more information contact:

EMCO Corporation

30475 S Wixom Road, Unit 125

Wixom, MI 48393

248-313-2700

info@emco-usa.com

www.emco-world.com