MAXXTURN 65 G2

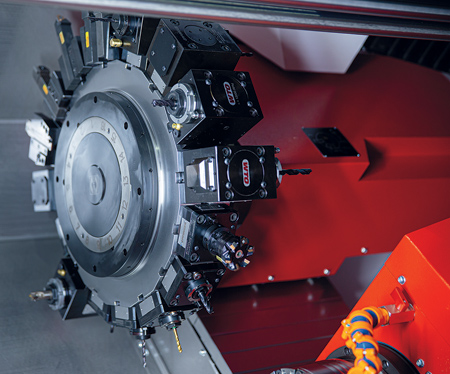

BMT turret with direct drive

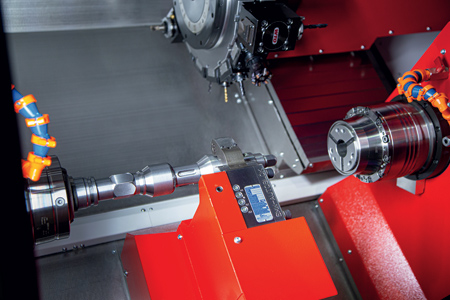

Steady rest for shaft machining

The MAXXTURN 65 G2 from EMCO Corporation has been completely redesigned. With its modular design, the machine offers a wide range of options for specific customer requirements.

"The high drive power of the main and counter spindles, combined with optimum torque characteristics, ensures economic efficiency in the machining of steel, as well as in the high-speed machining of aluminum," said a company spokesperson. "The 12 driven tools and a Y-axis provide enhanced results in complex milling and drilling operations. With numerous automation solutions and the EMCONNECT digital process assistant, the MAXXTURN 65 G2 is state-of-the-art and enables low-manpower production in operation."

Machine Structure

The core of the machine is the 40° inclined bed designed as a rigid and compact welded steel construction. Reinforcements provide additional rigidity in zones exposed to higher stress.

The optimized integration of the chip conveyor provides compact dimensions. Instead of belt drives, spindle motors are used on the main and counter spindles, allowing a wide speed range of up to 5,000 RPM and good concentricity properties.

Three main spindle sizes are available depending on customer requirements: Standard o65 mm, BigBore o77 mm and SuperBigBore o95mm. A symmetrically designed headstock, together with temperature sensors at the bearing points and liquid cooling, provide high thermal stability.

The C-axis is part of the basic machine equipment and allows the positioning of the spindle within a resolution of 0.001°. Due to the directly flanged encoder, the C-axis is suited for contour-precise milling. A hydraulic holding brake (optional) can be additionally activated. The Y-axis is also integrated in the basic machine structure and set at 90° to the X-axis. Short projection lengths form the basis for solid turning and drilling operations, as well as contour-free milling operations.

Absolute measuring systems are installed in all linear axes-position dispersion as per VDI3441 in XYZ: 0.0035/0.0035/0.004 µm as standard and 0.002/0.002/0.002 µm as an option, with glass scales and laser measurement.

Machine Configurations

The MAXXTRURN 65 G2 has numerous modular options and is available in different versions:

- MT65 G2 M: incl. tool drive, C-axis and tailstock

- MT65 G2 MY: incl. tool drive, C-axis, Y-axis and tailstock

- MT65-G2 SM: incl. counter spindle, tool drive and C-axis

- MT65-G2 SMY: incl. counter spindle, tool drive, C-axis and Y-axis.

On the MT65M-G2 with tailstock, the tailstock is mounted on the roller guide track and can be moved automatically over a length of 500 mm. A drag steady rest with O8-101 mm is optionally available. This provides even more flexible use of the machine, e.g. for shaft machining.

On the MT65S-G2 with counter spindle, the counter spindle head is seated on its own roller guide track and can be moved automatically over a length of 580 mm. The spindle is driven by an integrated spindle motor (ISM) with liquid cooling. A stroke-monitored parts ejector, flooded with coolant, allows safe removal of the finished parts.

A 12-station VDI30 turret (optionally VDI 40) with single-motor technology is available. A servo motor powers the driven tools or the swivel movement, resulting in no lift-off and indexing with directional logic. Each station can accommodate driven toolholders. Alternatively, a 12-station BMT55 turret with direct drive, with up to 12,000 RPM, or even a 16-station BMT45 turret can be integrated.

Control

The customer can choose between the SINUMERIK ONE or the FANUC 31i-B control system. The control panel on the MAXXTURN 65 G2 is height-adjustable on the right and can be swiveled, which ensures the best ergonomics. 22" multitouch screens improve the view of individual control functions.

The optional digital process assistant EMCONNECT stands for connectivity and networking of the production environment and helps with the comprehensive integration of customer- and system-specific applications around the machine control and the production process. EMCONNECT can be quickly updated and configured, and the selection of available apps is constantly being expanded. For example, the Shopfloor Management app serves as an option for machine and production data acquisition, enabling comprehensive monitoring of all machines and organization of processes in the production area. Apps for minimizing downtimes are also available with EMCONNECT.

Automation

The EMCO SL1200, IRCO ILS-MUK 7012 or 10012, FMB TURBO 5-65 or 8-75 and TOP AUTOMAZIONI X-FILES bar feeders are available for efficient production. The EMCO gantry loader ensures fully automatic loading and unloading of the workpieces and seamless interaction between the machine tool and the loading device. If required, flexible ROBOT automation can also be offered.

For more information contact:

EMCO Corporation

30475 S Wixom Road, Unit 125

Wixom, MI 48393

248-313-2700

info@emco-usa.com

www.emco-world.com