(l-r) Mark Perreault, VP Sales; Christopher Lockery, General Manager; Rich Brown, Wayne Baldwin, Tom Cassidy, Stephen Gentle and Andy Duffy, Sales Engineers; Alan Lockery, President; Viktor Niktchuk, Sales Engineer; and Joseph Halik, VP Operations

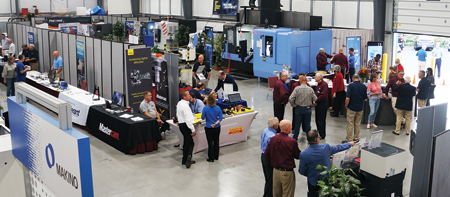

ABLE Machine Tool Sales of Agawam, MA, recently celebrated its 35th year in business with a three-day open house event held in its 11,000 sq. ft. showroom. Eight equipment manufacturers demonstrated a variety of machine tools under power, and 20 accessory vendors displayed their products and services. Taking reasonable precautions at this improved stage of pandemic recovery in New England, the event attracted well over 300 manufacturing guests.

"Our open house was fantastic," said ABLE's co-founder and President Alan Lockery. "I was not disappointed. Turnout was great. Our staff organizers, OEMs, vendors and suppliers came through with flying colors. People had a chance to see new technology and get ideas and recommendations. Along with our sales staff, our service staff was on hand to talk with customers about how they can maintain, improve and upgrade their older machines and processes. We learned. We shared. We had good food. And everyone had a good time."

"Up until a month before the open house, managers at ABLE crossed their fingers thinking about supply chain issues and getting machines for demonstration into the showroom on time," said a company spokesperson. "While New England has been doing well, many parts of the country were still fighting high rates of coronavirus. Naturally, ABLE's managers wondered how many people would attend in person or choose to stay away. But equipment manufacturers, vendor and associates provided product ahead of schedule, the showroom was well stocked and ventilated and guests attended in the hundreds. It was even possible for ABLE to offer machine specials and floor samples for sale, despite supply chain and transportation issues affecting the industry."

"The Open House was an opportunity for us to get to know local manufacturers and say thank you to our customers," said Lockery. "My staff talked to guests and listened to what they had to say. We all know there is a shortage of skilled labor and supply chain issues, but what else is going on? So, during the open house, my staff asked questions. Guests talked about successes, challenges and possible solutions regarding new machines, older machine upgrades, application processes, workflow adjustments, quality control and types of financing they might consider. If we want to understand what is going on in our region, and meet the needs, we have to ask questions directly of our customers and listen."

"There is a saying, 'behind your greatest fear is your greatest success,'" added the spokesperson. "The pandemic has magnified employment, distribution, financial and competitive issues and concerns for manufacturers and, in some cases, has changed the playing field.

"What I see changing the most in the next five to 10 years is automation becoming very important," said Kent Groff, Makino Regional Sales Manager. "You are not going to be able to find enough skilled labor, and customers are going to find a way to get around that. I am sure some fabulous innovations will come out of this."

"With the addition of automated features like simple cobots and loading systems," said Lockery, "manufacturers can increase production with fewer employees. The right technology can make it possible for machine operators to run two or three machines instead of one and produce high quality parts. That is the future."

When questioned, manufacturers expressed they were positive overall. They continuously look for new opportunities and ways to improve, grow and innovate their businesses while satisfying their customers. They are not waiting for "the new normal" to pan out, but rather are working on solutions. Some are training younger workers themselves, and some are offering incentives for older workers to stay on longer before retirement. Some are upgrading equipment. Some are buying new machines and accessories, or plan to buy in the near future when things settle down.

"ABLE represents a very large inventory of machine tools and helps customers obtain and integrate the right tools to meet the growing demand for precise, cost-effective parts," said the spokesperson. "A clear differentiator for ABLE is its large, flexible showroom that can be reconfigured many ways to fit the needs of the day. It has 26-ft. ceilings and a 16-ft. by 20-ft. overhead door on ground level. ABLE can take in any size machine its OEMs offer and install and test all accessories and software systems before delivery to the customer. ABLE is known throughout New England for streamlining the delivery process. This allows the customer to get their space ready. Installation at the customer's shop is efficient and takes a matter of days, not weeks, of continuous disruption to the shop floor. Customers are making parts within days."

"Working with ABLE is very positive. They have a good understanding of our operation, our needs and what solutions they could deliver to help solve our problems," said customer David Coburn of Morgan Technical Ceramics in Hudson, NH.

"When the floodgates open and pre-ordered machines start delivering," said Lockery, "we are ready to expedite everything we can and get machines to our customers ASAP."

ABLE provides machine tool sales, on-site service, technical support, pre-delivery integration of accessories, training and parts.

For more information contact:

Alan Lockery, President

ABLE Machine Tool Sales

253 Silver Street

P.O. Box 507

Agawam, MA 01001

413-786-4668

a.lockery@ablemts.com

www.ablemts.com