Metalex, located in Cincinnati, OH, has ordered a 6-axis gantry machining center from the Starrag Droop+Rein T series for the new Center for Advanced Large Manufacturing.

In a significant investment for the future, Metalex Manufacturing, located in Cincinnati, OH, has selected Starrag to supply a large-capacity, multi-axis Droop+Rein portal-type machining center for its new Center for Advanced Large Manufacturing.

The machine-the largest ever installed by the Cincinnati-based contract manufacturer-will provide it with flexible production capacity to meet all Metalex's foreseeable demands in terms of producing highly-accurate milled and turned workpieces in a single set-up.

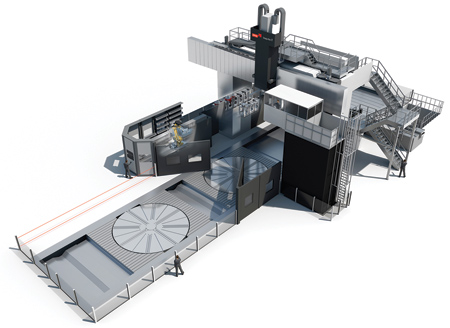

The 6-axis Droop+Rein T series machine is projected to not only satisfy existing projects, but its large machining envelope of up to 709" table length, 374" between the columns and 276" under the spindle will also attract new work.

The portal type milling and turning machine, which is being specifically configured to meet Metalex's current and future needs, offers an expansive 748" in X- and 354" in Y-axis. The 276" vertical clearance is covered by the 118" of ram stroke (Z-axis) and a continuously moveable crossrail of 217" (W-axis). The C-axis integrated in the ram with infinite rotation and the +/- 203° swiveling B-axis of the universal fork-type milling head complete the 6-axis.

The 136 HP main spindle transfers up to 66,372 ft-lbs. into the heavy vertical and horizontal milling head. A heavy-duty fork-type head and a spindle cartridge change fork-type head both enable 5-axis operation and a slim spindle extension rounds out the initial milling head configuration. All heads will be designed, built and tested by Droop+Rein in Germany. Furthermore, the machine will be prepared for more heads to be fitted in the future as new jobs arrive. The versatile 400 pocket robot tool magazine allows automatic loading of three different tooling systems into the selected milling and turning heads.

A distinctive feature is the table design. The X-bed carries two 236" x 315" tables that can be operated separately under the spindle while the other one is unloaded outside the machining area. Coupled in tandem, the tables can be extended to a length of 709" for machining extra-long workpieces. In addition, each table holds an integrated 236" rotary table that utilizes the 2 x 149 HP main drives to turn components of up to 440,925 lbs. (using one of the turning toolholders provided in addition to the milling heads) or to position as a C-axis for high accuracy milling and drilling operations. The result will be a one-stop precision machining source for extra-large components with complex geometry that require precision tolerances.

Established in 1971, Metalex is a performance-driven contract manufacturing company specializing in producing high-quality complex workpieces for a wide range of market leaders in the aerospace, energy, marine and consumer goods industries.

Metalex's desire to source a machine that would not only satisfy current production needs but also meet all projected demands in the years ahead saw it contact a number of machine builders, including Starrag, which in the past has supplied it with a number of machines (a Dörries vertical turning lathe and two Starrag STC horizontal 5-axis machining centers).

According to Droop+Rein Product Sales Manager Heiko Quack, "We sat down with Metalex to discuss what was needed-in short, a very flexible, large-capacity and high-accuracy machine with 5-axis capability that would efficiently accommodate a variety of parts in a range of materials and produced to tight tolerances."

"Applying our `engineering precisely what you value' philosophy, our relation with Metalex evolved by looking at various solutions and machine types available under the Starrag portfolio," continued Quack. "Together we arrived at the Droop+Rein T series, a portal milling machine that offers superb rigidity, essential for highly-accurate machining. We added the two rotary tables and the turning toolholders for in-cycle turning operations, and expanded the horizontal and vertical clearance to suit."

Quack confirmed, "With no comparative workpieces, from the outset we knew that Metalex wanted a machine that would meet all eventualities and, as always, Starrag applied the best world-class technology solutions including Balluff tool identification, Renishaw probing, BLUM laser tool measuring, video monitoring of the work area using four cameras, ARTIS tool and process monitoring and Brankamp collision monitoring all integrated via the machine's Siemens 840 D SL CNC system."

The machine is due for delivery in 2020 and production is scheduled to commence in 2021.

For more information contact:

Starrag USA Inc.

North American Headquarters

Skyport Business Park

2379 Progress Drive

Hebron, KY 41048

859-534-5201

ussales@starrag.com

www.starrag.com

Metalex Manufacturing

5750 Cornell Road

Cincinnati, OH 45242

513-489-0507

www.metalexmfg.com