Ethernet Communications System Enables Interactivity Across LNS Product Lines

November 1, 2019

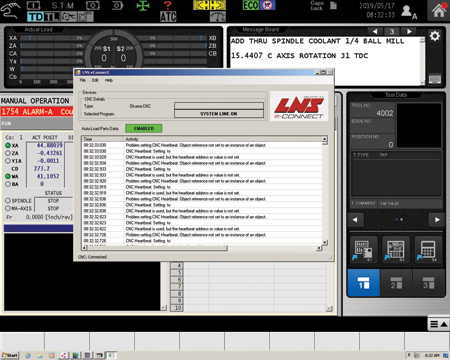

LNS e-Connect display showing current status of all data being exchanged between LNS bar feeder and CNC machine tool. Data is continually updated for all connected LNS peripherals.

The LNS e-Connect Ethernet communications system was originally developed to enable bi-directional data sharing between CNC machine tools and LNS bar feeders. These intra-machine communications monitor material usage and CNC production schedules to allow on-the-fly, automatic changeovers that reduce material waste and improve throughput to optimize manufacturing productivity.

e-Connect enhances the performance of additional LNS products, including chip and coolant management devices, high-pressure coolant and air filtration systems. "In all cases these interactive communications between devices and with remote monitors result in time and labor savings that improve overall manufacturing performance," said a company spokesperson. Specifically:

- e-Connect monitors LNS chip conveyors and reports whether or not the conveyor is online, if it is operating normally or if there is a fault.

- In the same way LNS ChipBLASTER high-pressure and filtration systems report pressure levels, warnings and faults through e-Connect. Additionally, high pressure coolant can be dynamically changed from the CNC machine tool cutting program.

- Because factory air conditions vary, LNS oil/coolant mist collectors will soon use e-Connect to monitor filter life so there is no guesswork regarding filter replacement.

All of these products interact with CNC machine tools through e-Connect to achieve greater efficiencies and cost-savings for an entire production process.

For more information contact:

LNS America, Inc.

4621 East Tech Drive

Cincinnati, OH 45245

513-528-5674

sales@lnsamerica.com

www.lns-america.com

< back