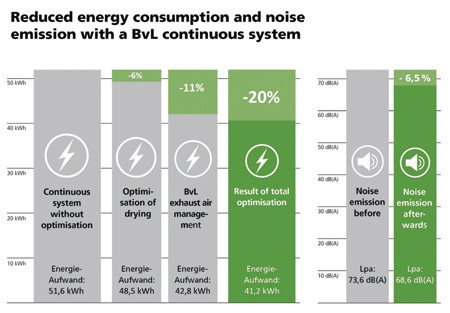

Energy and noise before and after the optimization measures, as well as individual results of the optimized drying process and the BvL exhaust management.

The Yukon BvL cleaning system at SAMAG provides optimum cleaning results with reduced energy consumption and noise emission.

Saalfelder Werkzeugmaschinen GmbH (SAMAG) in Germany produces crankshaft bearing caps for a large German automotive manufacturer. For the cleaning of these components, the company required a cleaning system with high cleanliness results, short cycle time and high level of energy efficiency.

SAMAG invested in a continuous cleaning system from the manufacturer BvL Oberflächentechnik GmbH in Germany. Special technical measures were installed in the cleaning system for SAMAG to optimize energy consumption and emissions.

In addition to insulation on the pipes, optimized drying and an automated stand-by state, the cleaning system was equipped with exhaust air management specially developed by BvL. The system has been in operation for one year and provides energy saving of 20% compared to a similar system without these energy efficiency measures. The absolute saving is 10.4 kWh, which means the total consumption of the system is only 41.2 kWh instead of 51.6 kWh. Additionally, water consumption was reduced by 20% and noise emissions were decreased by 5 dB(A).

"We have a very strong focus on the responsible use of energy resources in our company, and of course, we also keep an eye on the total operational costs of a system," said Andreas Weigel, head of maintenance at the SAMAG Group. "The amortization period of the energy saving package was very attractive, making it a worthwhile investment-not only with regard to environmental protection."

"In total, we can save around 71,000 kWh/a in three shift operations," continued Weigel. "That corresponds to an impressive annual CO2 saving of 41 t. Compared to other industry standard systems, this can lower the expected consumption by a whole 20%."

The exhaust air management developed by BvL reduces the volume of exhaust air, which consumes the most energy in a continuous cleaning system. To achieve this, the system measures the moisture content in the drying zone and extracts only as much air as necessary for the process. This creates the best possible moisture level in the system and the volume of hot exhaust air-and therefore energy-blown out of the system is kept as low as possible. The warm and most air, and with it the energy, remains in the system.

Sound level measurement at SAMAG was carried out at the measuring positions in line with DIN 45635 part 1 as well as at a user-related measuring point defined by SAMAG. According to the DIN measurement, the system achieves a workplace related emission value of LpA: 68.6 dB(A). "It is interesting to compare this to a structurally similar system from 2012 without optimization because this reached a value of 73.6 dB(A). This proves that the significant noise reduction is due to the optimization measures," said Weigel. "In the same way, the BvL system achieved a value of 75 dB(A) at the user-related measuring point directly at the discharge position defined by us. This is below the limit value stipulated in the requirements specification. The reduced noise emission is particularly important in our company because we are continuously striving to improve the working environment for our employees."

To reduce noise emissions, Weigel said the speed of the fan in the drying phase was reduced. "The perfect ratio of low flow and high temperature provides an optimum drying result with minimum noise emission," he said.

Based on these positive experiences, SAMAG decided to buy another cleaning system of the same type from BvL. Moreover, all cleaning systems in the production workshop were retrofitted with the special exhaust air management to achieve further energy savings.

For more information contact:

Scott Knoy, President

German Machine Tools of America

4630 Freedom Drive

Ann Arbor, MI 48108

248-921-0122

scott@gmtamerica.com

www.gmtamerica.com