Sunnen and Applied Nano Surfaces have entered into a joint market development agreement to advance technology and applications based on the patented Triboconditioning process. The process uses a Sunnen SV-2115 vertical hone to reduce friction and wear on various steel and cast-iron surfaces while improving surface finish, preventing seizures and enhancing product life.

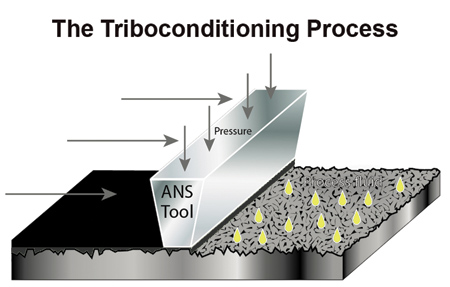

Triboconditioning is a combined mechano-chemical surface treatment process that uses a machining procedure to level off surface peaks and apply a friction- and wear-reducing compound to the component surface. The process is designed to be cost-efficient in mass production environments, making it suitable for in-house manufacturing as a part of component manufacturers' production lines.

Sunnen Products Company and Sweden's Applied Nano Surfaces (ANS) have entered into a joint market development agreement to advance technology and applications based on the unique Triboconditioning process recently patented by ANS. The process reduces friction and wear on various steel and cast iron surfaces while improving surface finish, preventing seizures and enhancing product life.

"ANS is on the leading edge of friction reduction technology," said Chris Miltenberger, President and CEO of Sunnen Products Company. "We are excited about working with ANS on the development of new products and surface finishing methods that will bring unique solutions to all segments of the manufacturing industry.

Triboconditioning is a combined mechano-chemical surface treatment process that uses a machining procedure to level off surface peaks and apply a friction- and wear-reducing compound to the component surface. Unlike spray coatings, the compound becomes an integrated part of the component structure at a nano level. The process is mechanically simple and, in most cases, can be done with Sunnen precision honing equipment. It is cost-efficient in mass production environments, making it suitable for in-house manufacturing as a part of component manufacturers' production lines.

Key applications include automotive engine components such as valve train parts, cylinder liners, crankshafts and connecting rods, as well as industrial applications such as hydraulic motors, rock drills, pumps, chains, gears and compressors.

"ANS is looking forward to combining our knowledge of friction reducing technology with Sunnen's expertise in surface finishing," said Christian Kolar, CEO, Applied Nano Surfaces Sweden AB. "The solutions under development have the potential to be a real game-changer in component efficiency and product lifetime."

For more information contact:

Sunnen Products Company

7910 Manchester Road

St. Louis, MO 63143

800-325-3670 / 314-781-2100

sales@sunnen.com

www.sunnen.com

Applied Nano Surfaces

www.appliednanosurfaces.com