Moving towards a digital factory with Integrated Digitization

Secure networking of DMG MORI machines.

WERKBLiQ allows secure and complete documentation of maintenance processes and offers simple and interdivisional communication.

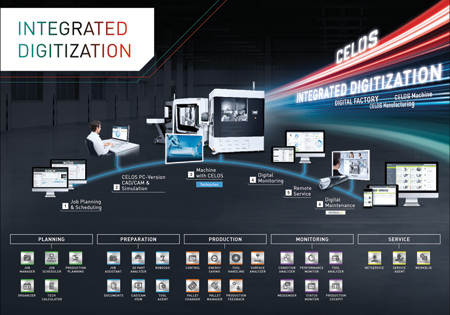

The trend towards industrial digitization is fundamentally altering the framework conditions for metalcutting production technology. DMG MORI's machines have been offering digitization solutions since 2013 with the CELOS app-based control and user interface. At the same time, DMG MORI has been consistently expanding the range of solutions it offers to create an open ecosystem for the digital factory. In addition, DMG MORI is increasing its portfolio of CELOS services with intelligent software solutions and connective hardware.

Since 2013, CELOS has been playing a key role in the DMG MORI Group's digitization roadmap. More than 14,500 CELOS machines have been installed on the market. Over 100 high-tech machines from DMG MORI's portfolio are now powered by CELOS, whereby overall availability is implemented within a short space of time.

The number of CELOS APPs has also steadily grown over the years. Due to the 11 new apps, there are now a total of 27 CELOS APPs for planning, preparation, production, monitoring and service in the workshop available. With CELOS, customers receive intuitive, consistent solutions as an integrated basis for paperless digital production.

CELOS with New Prospects

DMG MORI has also further developed its CELOS control and user interface to create consistent digital workflows for efficient production. In the current CELOS version the focus is on digital workflows for digital work preparation and digital monitoring. At the same time, DMG MORI is working on the topic of connectivity and is developing specific products such as the IoTconnector for consistent and secure networking in production.

From Vision to Reality with Integrated Digitization

DMG MORI's current digitization initiatives are based on the vision of the digital factory, which is characterized by adaptive factory structures. The digital factory's key feature is the automatic, data-based adaptation of processes in production to changing framework conditions.

"We are focusing particularly on small and medium enterprises (SMEs)," said Lawrence Chan, Vice President of DMG MORI Software Technology Solutions USA, Inc. He explained that the possibility of gradual and individualized entry into digitalized manufacturing and production is the key. In this regard, the performance commitment now no longer just applies to the company's own high-tech machines, since even existing machines from DMG MORI can be networked with the IoTconnector.

IoTconnector - Secure Networking of DMG MORI Machines

Features of IoTconnector:

- Interfaces enable data exchange between the IoTconnector and functionalities

- Due to its integrated firewall, the IoTconnector increases IT security and protects the machine from access by unauthorized third parties

- Networking of older-generation DMG MORI machines with CELOS by using the IoTconnector Retrofit-Kit.

CELOS with HEIDENHAIN

Features of CELOS with HEIDENHAIN (availability based on machine model):

- CELOS from DMG MORI with 21.5" ERGOline and HEIDENHAIN TNC 640

- 22 introductory-level CELOS Apps available

- Global program setting - subsequent adaptation of a CAM NC program directly on the machine

- DXF converter - CAD import

- Tool-based machining

- Simple and efficient use of face grinders.

Keeping Workflows Under Control with CELOS Manufacturing

Even the latest software developments are increasingly gaining in importance and added value. Workflows and machining processes can only be digitally mapped, controlled and optimized with a consistent dataflow in the shop floor area.

NETservice - Direct Access to the Digital Service

To restore machine availability quickly and easily, DMG MORI offers the new NETservice. The NETservice has been specially developed for the high demands of customers in the machine tool industry. Main user advantages include the multi-user conference, the maximum data security and the optional plug & play connection of the SERVICEcamera from DMG MORI.

The connection of the optional SERVICEcamera enables the livestream from the machine directly to the DMG MORI Hotline. This visual support of the phone and online sessions with the DMG MORI Service Experts leads to significantly higher solution rates.

A Gradual or Integral Way Towards the Digital Factory

DMG MORI offers its customers the opportunity to either implement comprehensive, customized end-to-end solutions with CELOS' digital products and software systems, or to gradually transform their company into a digital factory - for high transparency, effective processes, maximum availability and the best possible production reliability.

Unique Solution to Industry 4.0 and IIoT with CELOS Club

CELOS Club includes various applications and services designed to maximize the use of CELOS and significantly boost customers' productivity. The package is engineered to ensure the best and latest machine conditions at all times and accommodate the impacts from a rapidly changing market environment. Annual upgrades of the CELOS software keep the machine always up-to-date with the latest technologies and new functions.

Providing various software solutions such as DMG MORI Visual Programming, Manufacturing Suite NC simulation and CELOS PC-Version, CELOS Club enables efficient machine management. Additionally, the DMG MORI MESSENGER increases productivity by constant machine monitoring, while NETservice offers remote diagnosis by qualified DMG MORI Service Experts. This reduces machine down time and maintenance costs.

A further advantage of CELOS Club is the opportunity for budget savings - there is a 20% discount on selected MAPPS V software options - and a 50% discount on the spare parts for ERGOline touch in case of failure.

WERKBLiQ - Optimizing Maintenance of the Entire Machine Park

Machine availability can be significantly increased by efficiently controlling service resources. WERKBLiQ GmbH is a daughter company of DMG MORI, that, with its web-based and multi-vendor platform, sustainably optimizes the management of service and maintenance of the entire machine park for customers. WERKBLiQ ensures secure and complete documentation of maintenance processes and offers simple and cross-departmental communication. The platform networks all those involved in the maintenance process and, with a total of 15 modules, offers fast commissioning of technicians directly from the machines, minimizes downtimes through adherence to maintenance and enables spare parts to be procured quickly, among other features. This allows DMG MORI to offer an integrated digitalization strategy at all levels of value creation.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com