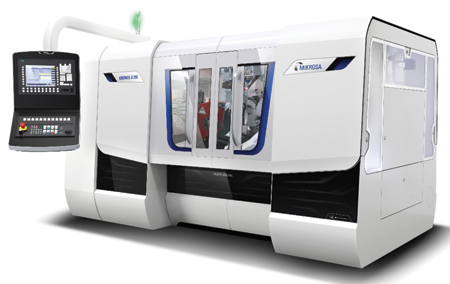

MIKROSA KRONOS S250 - side

MIKROSA KRONOS S250 - front

"The KRONOS S 250 centerless grinding machine from MIKROSA is not only highly productive and precise, but it can also be changed over very quickly," said a company spokesperson. The machine is suitable for customers with a wide range of parts.

"The KRONOS S 250 combines the best grinding qualities with high grinding speeds. The machine is characterized by its unique machine concept with cross-slide systems on the grinding and regulating wheel side," added the spokesperson. In addition to through and plunge grinding, this also allows for the combination of several work operations in one machine. The spindle unit can be inclined by 6°. Thus, the targeted precision grinding of diameter and face in only one operation is possible.

Regardless of the grinding process, the cross slides with highly dynamic digital drives offer increased precision and enhanced dynamics. The number of axes required is reduced from 6 to 4, while the high machining flexibility is maintained. The Granitan machine bed offers a high thermal stability and optimal vibration damping.

However, this compact and versatile machine is not only suitable for machining large series. "Grinding and regulating wheels, dressing tools, work rests and workpiece-dependent automation components are replaced so quickly that changeover from one batch to another requires very little time. This is ensured by a newly developed quick-change gripper system for mechanical and vacuum grippers as well as quickly exchangeable shuttle V-blocks. In addition, many of the necessary settings are made electronically. Quick changeover times, high process reliability and repeatable results are thus guaranteed," said the spokesperson.

The KRONOS S 250 centerless grinding machine is therefore suitable for grinding large series as well as for machining smaller batch sizes - ideal for companies with a wide range of parts. The machine has a fixed grinding zone, which enables simple automation or interlinking. The KRONOS S 250 can be equipped with a loading gantry and shuttle or with charge and discharge storage belts for cost-effective machining of a variety of parts in different batch sizes.

Technical data:

- Workpiece diameter: 1.5 - 35 mm

- Workpiece length for plunge grinding, max.: 245 mm

- Grinding wheel: O 450 x 250 x 203.2 mm

- Drive power: 15 kW

- Peripheral speed (CBN): 80 m/s (120/150 m/s)

- Regulating wheel: O 250 x 250 x 127 mm

- Drive power: 5 kW

- Dressing speed: 1,000 RPM.

For more information contact:

UNITED GRINDING North America Inc.

2100 UNITED GRINDING Blvd.

Miamisburg, OH 45342

937-859-1975

info@grinding.com

www.grinding.com