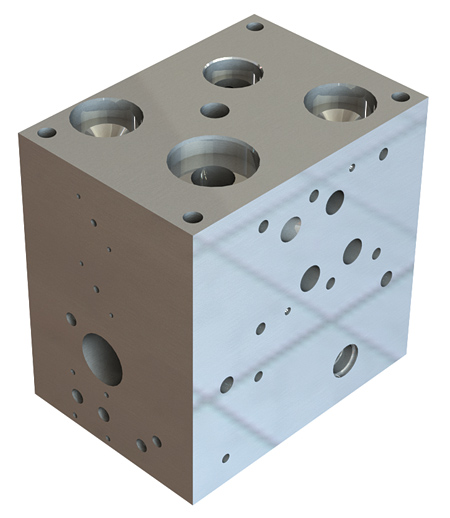

Original block manifold. Flow passages are cross drilled and plugged to direct flow.

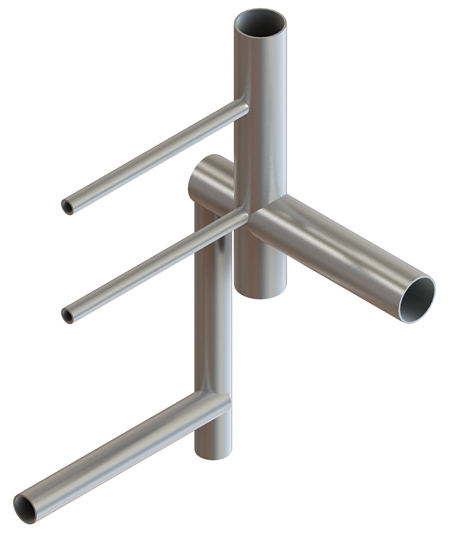

Extracted flow path section highlighting abrupt junctions.

Flow path section generated after CFD analysis; severity of corner angles have been reduced for optimized flow.

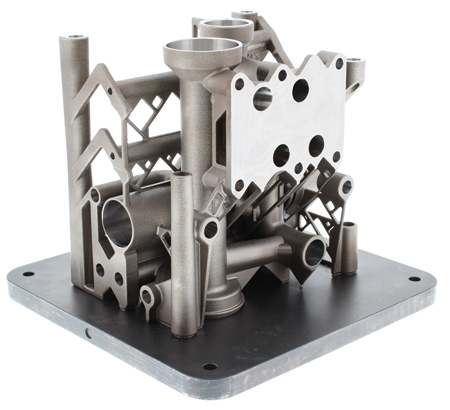

Second iteration geometry. The block extraction passages have been removed and the support structures reworked for increased stiffness and rigidity.

As additive manufacturing (AM) continues its migration to the shop floor, Renishaw is working directly with customers to enhance part designs, increase production efficiency and improve overall part performance using the latest AM technology. The company recently collaborated with a customer to redesign and produce an existing hydraulic block manifold design using AM, with excellent results. The main goal of the project was to reduce the mass of the component while retaining its robustness. Due to the increased design freedom associated with AM, an opportunity to increase the efficiency of the flow paths was also identified. Ultimately, part mass was decreased by 37% while flow efficiency received a 60% boost.

Hydraulic block manifolds direct the flow of fluid in a hydraulic system linking valves, pumps and actuators. It enables the design engineer to manage the operation of a hydraulic circuit while combining the components in a compact unit. Traditionally, hydraulic block manifolds are manufactured from an aluminum alloy or stainless steel billet, which has been cut and machined to size, followed by drilling to create the flow pathways. Specialized tooling is often needed due to the complex drilling that is required. Passages require blanking plugs to properly direct flow through the system.

The nature of the manufacturing process results in abrupt angled junctions between flow paths, which can cause flow separation and/or stagnation - a major contributor to efficiency loss.

Aluminum alloy manifolds are generally less costly due to lower material costs and ease of machining. However, they can be less abrasion resistant, so any loose particles in the flow will abrade the surface and increase wear. For this reason, stainless steel manifolds are sometimes more desirable. However, due to the higher density and hardness of stainless steel compared to aluminum alloy, these come with a significant weight increase and added cost of machining.

Production benefits of AM for the design and manufacture of hydraulic manifolds include:

- Optimized flow paths for a more efficient component functionality

- Ability to fully utilize computational fluid dynamics (CFD) to aid the design process

- Reduction in the requirement for fixturing

- Minimal requirement for removable support structures

- Elimination of the requirement for block extraction passages.

These result in part mass reductions of up to 79%, and the single piece construction presents fewer opportunities for defects. Other benefits include rapid part design and development iterations, compatibility with existing designs and improved flow efficiency of up to 60%.

Redesign for AM - Design Scope

AM allows a higher level of design freedom, so the component geometry could be adapted for AM to reduce material mass and improved functionality within the same space. Renishaw was given certain design and function guidelines by the customer, which had to be considered when redesigning the component. These included defined connection ports, inner diameters of flow passages, wall thicknesses of the flow passages, and fixture points and interfaces.

The customer's main requirement was weight reduction while still maintaining the part's rigidity and functionality. Renishaw design engineers also recognized scope in the redesign for AM to improve the efficiency of the flow paths within the system.

First Design Iteration

The first step was to deconstruct the part into just the essential passageways that provide the functionality of the hydraulic block manifold. The flow paths of the original cross-drilled design were extracted using CAD software, and any drilled areas not required for the flow path were removed, leaving the essential pipe network. Each hydraulic circuit was then reduced and simplified in preparation for piece-wise computational fluid dynamics (CFD) analysis using SOLIDWORKS Flow Simulation. Next, the flow paths were optimized after identifying areas of flow separation and stagnation gained via the CFD analysis.

Wall thickness was generated based on the customer specification, but this could also be done using finite element analysis (FEA) stress modeling, based on pressure readings taken during CFD analysis.

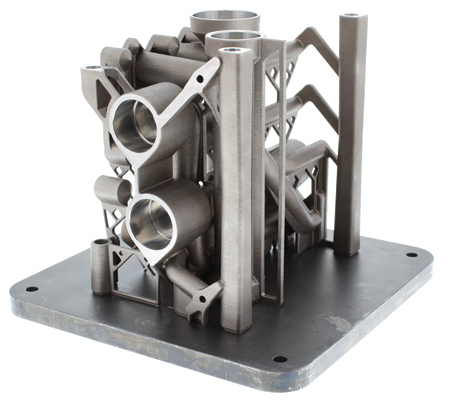

Finally, permanent support structures were designed and added in to the CAD geometry, creating a self-supporting, efficient structure. Generally, support structures are added to a final geometry in post-processing of the component design in order to anchor the object to the baseplate and dissipate heat. However, making the supports part of the component design reduces the potential waste material associated with removable support structures or anchors.

The first design iteration resulted in a reduction in volume of 52% compared to the original block manifold, as well as an improvement in flow efficiency of up to 60%.

Second Design Iteration

The original manifold was designed for modular use, with multiple units installed in series. Individual hydraulic block manifolds will occasionally need to be extracted from the line-up for servicing, making it necessary to include threaded "block extraction" passages.

The first iteration for AM geometry had features that an engineer could use to extract the manifold manually without the use of tools, negating the requirement for the block extraction passages. While the removal of these block extraction passages from the CAD model immediately disrupted the intricate network of self-supporting structures, this was seen as an opportunity to redevelop the design.

It had been suggested that iteration one might be subjected to flexure, torsional distortion and/or chatter during machining due to the now reduced volume of material relative to a solid block. While simultaneously increasing its stiffness, the redesign resulted in a final part that was just 21% of the volume of the original.

This significant reduction in volume now opened up the option of producing iteration two in the more desirable stainless steel 316L. This resulted in a net reduction in weight of 37%, even in a material with higher density (8 g/cubic cm for stainless steel and < 3 g/cubic cm for aluminum alloy).

Results Summary

The results summary is as follows, showing design stage, material, volume (cubic cm) and mass (kg):

- Original hydraulic manifold, aluminum alloy, 9,600, 25.6

- Design for AM first iteration, aluminum alloy, 4,650 (-52%), 12.3

- Design for AM second iteration, 316L stainless steel, 2,040 (-79%), 16.3.

"The Renishaw approach to AM wants users to understand that designing for AM has a higher level of freedom compared to traditional manufacturing techniques, such as subtractive machining and casting," said a Renishaw spokesperson. "For companies considering integrating AM into their production processes, Renishaw's global Solutions Centers act as a gateway to entry. The Solutions Centers provide a secure development environment where customers can expand their knowledge and confidence using AM technology. The Solutions Centers are equipped with the latest AM systems and staffed by experienced engineers to allow fast access to deploying the technology, all at fixed predictable costs."

For more information contact:

Renishaw Inc.

1001 Wesemann Drive

West Dundee, IL 60118

847-286-9953

usa@renishaw.com

www.renishaw.com/additive