Long-Drill Grinder with Integrated Wheel and Nozzle Changer

June 1, 2017

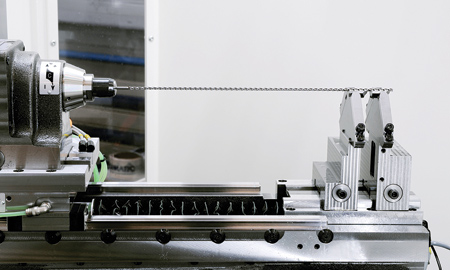

GrindSmart 528XF grinding a ultra-long deep-hole drill from blank in one set-up including point

Rollomatic, a machine tool manufacturer based in Le Landeron, Switzerland, offers a 6-axis CNC tool grinder for long drills.

In-depth tests in the field have shown that the new GrindSmart 528XF with SmartChanger is suited for long drills. This machine is furnished with a traveling workhead allowing drills with a flute length up to 12" to be efficiently produced. In addition, its versatility permits other carbide or HSS drills and high-performance end mills to be manufactured.

Features include:

- Camera to locate small coolant holes and a 6-station wheel/nozzle changer.

- New, patented and proprietary drill steady rest that can compensate for back taper as well as a combination of back taper and cylindrical drill relief. This steady rest is dedicated for drills.

- New feature for neck grinding of long-reach end mills

- Newly designed CNC traveling workhead as the 6th axis.

- Option for locating small coolant holes down to 0.05 mm.

- 6-station wheel/nozzle changer with HSK50E arbors, tested for repetitive concentricity of less than 2 microns.

- 20 HP synchronous direct-drive grinding spindle offers constant RPM with no chatter marks in flutes, as opposed to conventional asynchronous motors, to provide super-sharp cutting edges.

Rollomatic provides service/support from its North American headquarters in Mundelein, IL, and satellite offices in CA, IN and MA.

For more information contact:

Rollomatic Inc. USA

1295 Armour Blvd.

Mundelein, IL 60060

866-713-6398

solutions@rollomaticusa.com

www.rollomaticusa.com

< back