South Texas College's Dual Enrollment program partners the college with approximately nine local high schools.

In order to keep everything consistent so that the same degree or certificate is awarded to all students, each school is required to purchase the same CNC machines and CAM software that are used in the college's own shop.

The schools that have successfully landed grants from the state are able to build entire labs in order for their students to earn associate degrees as part of the College's Early College program.

Morales said that when students take a 0.000125" step over a 3/4" depth and machine through a piece of aluminum - and the chips start flying - it blows them away.

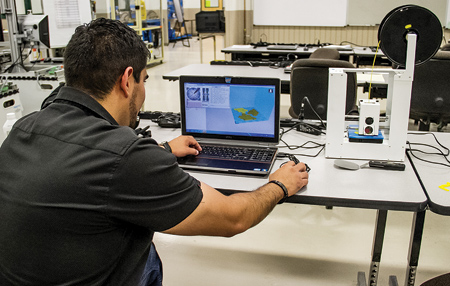

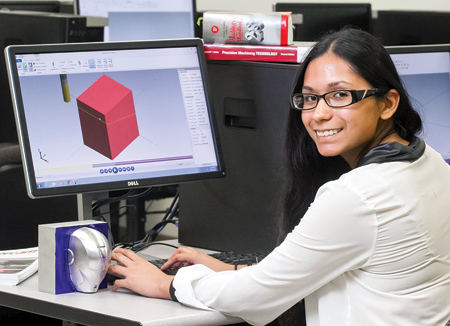

Students learn how to draw a part in a CAD environment using the software's SOLIDWORKS plug-in and then need to answer questions such as: How would you machine this?

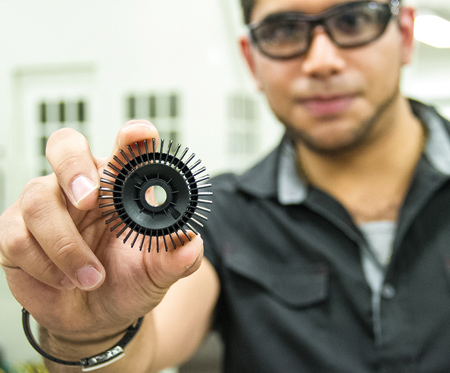

Students draw upon all of their previous two to three semesters of experience to make more complex parts such as this.

The CAD/CAM software's Dynamic Motion toolpaths use proprietary algorithms to detect material changes in the part rather than just following the geometry. This causes the tool to remain constantly engaged with the part, decreasing air cutting time and tool breakage and resulting in a constant chip load.

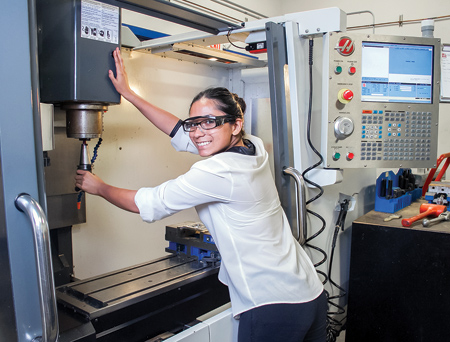

The students need to get familiar with the noises that the machines make because the CAM programs are good at showing what is going to happen in a virtual environment, but it is up to the instructors to provide the real-world experience as well.

Most of the school sites are equipped with Haas tour mills, mini mills, a GT lathe and tool lathe.

There is no set national or statewide curriculum for South Texas College's program. They set the rules for what is best for the students - the software, programs and equipment that best suit the industrial environment and the learning environment.

Twenty-first century manufacturing looks very little like that of our fathers or grandfathers. Gone, for the most part, are the dirty, soot-filled factories of the past and in their place are cleaner versions with large machines that cost as much as a luxury car and perform just as well. The challenge for schools with manufacturing technology programs is that to recruit more students they need to effectively erase the concept of the former and educate kids and parents alike about the latter. The Advanced Manufacturing Technology Department at South Texas College's McAllen, TX, campus has a leading-edge approach to promoting manufacturing as a career choice that has been studied by other school systems and institutions throughout the country.

The Advanced Manufacturing Technology Program

There are several certificates and degrees offered by South Texas College, tailored toward the individual needs of the student. The Fast Track degree is a one-year program that covers blueprint reading, basic machine operation and mathematics but stops short of CNC programming. The full one-year certification program covers everything in the Fast Track degree plus 3-D parametrics to G- and M-codes to CNC programming and CAM. According to Daniel Morales, one of the pioneers of this program and a former precision manufacturing instructor, the college has a large dual enrollment program through its affiliation with roughly nine local high schools. In order to keep everything consistent so that the same degree or certificate is awarded to all students, each school is required to purchase the same CNC machines (Haas from Haas Automation, Oxnard, CA) and CAD/CAM software (Mastercam software from CNC Software, Inc., Tolland, CT) that are found in the college's own shop. The effort to get everyone on the same page is not always easy since some schools have deeper pockets than others.

"We have had to go to school board meetings and petition members with what we are doing with this $50,000 for CNC machines and CAD/CAM software licensing," said Morales. "They are receptive to it but it is a constant battle to stay on their agendas. You need to have a plan to integrate students to graduate with a certificate in manufacturing technology - get me a CNC mill this year, CAD/CAM software in the second year and a CNC lathe in the third year. By breaking it down, the purse strings are more likely to open." The schools that have successfully landed grants from the state, such as Weslaco Independent School District, are able to build entire labs in order for their kids to earn full associate degrees as part of the college's Early College program. Unlike the traditional manufacturing program that begins during a student's junior or senior year, the Early College trajectory is open to accepted freshmen who continue to work throughout their four high school years to earn the associate degree.

There is no set national or state-wide curriculum for South Texas College's program. "We get to set the rules for what is best for our students - the software, programs and equipment that best suit the industrial environment and the learning environment," said Morales. "We are aware that people look at what we do, what software and what curriculums we are using. The things we do, other schools adopt." The team relies heavily on its advisory board, which is made up of seven local manufacturing companies, to ensure that the kids are learning the skills they will need to get jobs and retain them. Plant managers review and audit the programs once per semester and provide suggestions if necessary.

There are eight full-time members of the college faculty that teach at its various campuses or at participating high schools. Approximately five adjunct faculty members divide their time between their day jobs and teaching at night. Finally, about six or so high school teachers, many of whom were manufacturing or mechanical engineers prior in life, work alongside the college faculty at their respective schools. "Maybe one of their teachers will teach blueprint reading with precision tools with a stellar engineer who is teaching with us," said Morales. The school districts prefer their own instructors teach these courses, prompting South Texas College to initiate its Faculty Learning Community (FLC) in which the college offers a year and a half of intense faculty training to get them up to speed.

Equipping Students for Learning

"There are companies that come in and want to sell you machines and equipment and software," said Morales, "but there is no curriculum behind it and we end up having to spend our time creating it from scratch. Sometimes with our faculty duties it is not possible." When deciding which software to use to teach the CAM portion of the program, the faculty wanted a strong, established software product that was standard in most shops, had good tech support, was easy to learn and came with a sound curriculum behind it. They chose Mastercam because it ultimately exceeded their basic criteria. "The curriculum that is available is very strong and so is the tech support," said Morales. The program uses not only general Caminstructor books but also relies heavily on the Mastercam University library of materials, hands-on projects and courses, and the emastercam.com In-House Solutions textbooks.

The solid relationships the college has built with both their industrial supplier, MLC CAD Systems (Austin, TX) and educational supplier Teaching Systems, Inc. (Arlington, TX) have provided all faculty with the appropriate training to teach the courses well. "We were invited to CNC Software for training. If we want to teach these technologies, we as instructors have to be prepared for it and there has to be a system to prepare the faculty for these programs," said Morales. "One of my colleagues and I traveled to Connecticut, learned as much as we could about the software and multi-axis technologies and brought what we learned back and communicated it through our FLC program."

Each participating high school has between three and 12 seats of Mastercam. This particular CAM software fits the South Texas College program in that it is easy to use and, despite improvements and updates that are introduced periodically, it is not disruptive to learning. "We modeled a 5-axis trunnion and simulated cutting of a 5-axis part, making sure that we did not plunge a tool into a $50,000 trunnion table," said Morales. The software's Dynamic Motion technology takes the hands-on lessons to a whole new level. Proprietary algorithms programmed into the software allow it to detect material changes in the part rather than just following the geometry, allowing the tool to remain constantly engaged with the part, decreasing air cutting time and tool breakage, and resulting in a constant chip load. Morales said that when they take a 0.00125" step over a 3/4" depth and machine through a piece of aluminum - and then the chips start flying - it blows the kids away. "It is an eye-opening experience," he said. "You have to get the kids used to the noises that the machines make because the CAM programs are really good at showing you what is going to happen in a virtual environment - but as far as showing you, that is a whole experience that we have to be able to provide as well." Most of the school sites are equipped with Haas tour mills, mini mills, a GT lathe and tool lathe.

CAD for CAM

Students learn how to draw a part in a CAD environment using SOLIDWORKS and the Mastercam for SOLIDWORKS add-in and then need to answer the questions: How would you machine this? What kind of cutter is appropriate? Is this part going to be turned and then milled? Is this part going to be straight milled? How many set-ups will it require? "They need to draw upon all of their previous two to three semesters of experience to make the piece," said Morales.

Doors Open for Everyone

A large part of the success of the South Texas College program is the awareness initiative that involves educating public school administrators, counselors, teachers and other stakeholders on the realities of 21st century manufacturing. They are invited to STEM workshops where they receive hands-on experience once per semester and learn about the importance of manufacturing to the McAllen area. "Many do not understand it," said Morales. "They think they are going to send a student to work in a dirty, grungy shop and cannot prepare the kids for that. So we brought them in and showed them what modern contemporary manufacturing is - high tech, high precision, clean environment - and they get excited about it." The college also attends career fairs at elementary schools to expose the kids to manufacturing. In fact, they host a summer robotics camp for kids ages eight and older.

South Texas College is also investing in its future. When the economy took a plunge, so did the McAllen area. Located in Hidalgo County, across the Rio Grande River from the Mexican city of Reynoso, McAllen and the surrounding area has a vibrant migrant population that works primarily in low-income or agricultural jobs. The certificate and early college programs have been instrumental in providing these kids with opportunities they otherwise would never have known existed. Morales has seen his students graduate, make a living wage, buy houses, finish bachelor's degrees and move on to high-tech jobs, such as making race car components or components for Joint Strike Fighters. Some have moved on to other manufacturing careers unrelated to machining or programming. "The point is, they have the opportunity to live the American dream," said Morales.

Everyone Has a Stake

Morales has seen manufacturing as growing rather than declining. Job shops also have a role in attracting new talent and making these jobs more appealing to kids. "You go to a lot of shops and they are located in a building that is painted tan with a little sign on the door that says the company's name. You would never guess there are millions of dollars invested in that plant," he said. It is not just the colleges and technical schools that need to raise awareness and draw students in - it is a collective effort amongst all stakeholders. He was especially grateful for the involvement of the advisory board because they help promote manufacturing on a grassroots level. As for the faculty of South Texas College, led by Esmeralda Adame, Assistant Professor of Precision Manufacturing Technology, they are set to begin another year of teaching 21st century manufacturing to a whole new set of wide open eyes.

Morales recently entrusted the program he helped build to his colleagues in order to start his own manufacturing business, showing his students another one of the great things about a career in manufacturing: the ability to start your own business and be your own boss.

For more information contact:

South Texas College

P.O. Box 9701

McAllen, TX 78502-9701

800-742-7822

information@southtexascollege.edu

www.southtexascollege.edu