Comparison of leveled and unleveled sheet metal after robotic welding

Whether it comes from a service center or an upstream process, most sheet or plate will contain residual stress (shown on left sample), compared to the same material (on right) after processing in a parts leveler, according to Nicholas Miller, Technical Director at ARKU Coil Systems.

The servo-hydraulic leveler adjusts its force instantly to compensate for the varying cross section of parts with large cutouts and perforations or shapes such as triangles and circles.

A free-standing servo-hydraulic leveler integrates into fab shop workflow to supply stress-free parts for bending, assembly or welding.

Parts leveling can relieve your production frustrations caused by metal components loaded with internal stresses that are released during welding, laser cutting, punching or bending.

"The material coming from a service center has probably been leveled at some point, but most metals retain internal stresses and a degree of coil defects that make set-up, processing or assembly difficult downstream," said Nicholas Miller, Technical Director at ARKU Coil Systems. Material that appears perfectly flat may have internal stresses that are released during stamping, cutting or bending. According to Miller, this occurs because most upstream leveling processes do not sufficiently work the material past its yield point, which is key to realigning the stresses in a single direction.

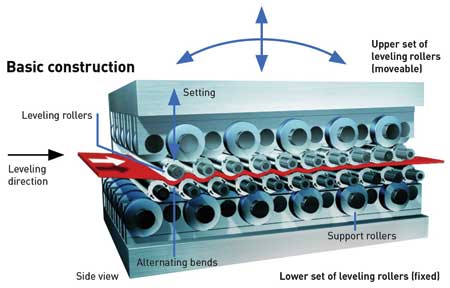

Miller stated that the servo-hydraulic parts leveler is uniquely designed for this purpose. "This type of leveler uses a series of closely-spaced, small-diameter rollers - supported by large rollers to prevent deflection - to bend material sharply through a wave-like path to stretch the metal past its yield point," he explained. After the initial sharp bend, the material is gradually returned to a flat state as it passes through the leveling rollers and exits the machine. Small-diameter rollers with a small roller pitch produce a sharper bend, ensuring the material is stretched past its yield point.

Miller explained that the effect on material is different from a gantry hammer press, press brake, roll former, flame and hammer or any other leveling method. The hydraulic leveler also works quickly and often gives the desired result on the first pass while others require multiple hits and checks. "And it does not take an expert to achieve great results on the first pass," Miller continued. "It can take years for an operator to become an expert with a hammer press, and if that person leaves your company, it is a real handicap. Even in the hands of an expert, a hammer press cannot stress-relieve parts, though they might appear flat."

According to Miller, the servo-hydraulic leveler is versatile because it is "smart." Servo-hydraulics adjust the leveling force instantly to compensate for the varying cross section of parts with large cutouts and perforations or shapes such as triangles and circles. The mechanical leveler on a coil line is not designed to do this. According to Miller, the hydraulic leveler is also ideal for appearance critical parts required for medical, packaging machinery, food, beverage and scientific applications. In addition, heat does not cause marring, slag or discoloration during this process.

"Fast leveling capability on the factory floor is a proven way to increase productivity and reduce rework," stated Miller. "Welding robots find seams reliably with leveled parts. Set-ups are faster. Welding, cutting and bending results are more predictable. As a bonus, you can salvage material that does not meet flatness specs as it comes from the service center." For more information, watch videos at www.youtube.com/ARKURichttechnik.

For more information contact:

ARKU Coil Systems, Inc.

11405 Grooms Road

Cincinnati, OH 45242

513-638-8554

www.arku.com