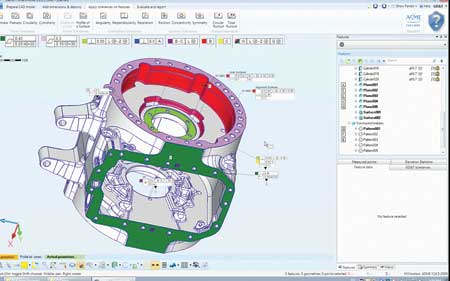

SmartProfile 3 provides detailed feedback for rapid machining adjustments.

KOTEM, a division of Quality Vision International (QVI), has released the latest version of 3D GD&T analysis software, SmartProfile 3. SmartProfile provides analysis of part measurements compared to the part's CAD model, and can be used to confirm design intent and GD&T compliance for Shape, Form, Profile, Orientation and Location on any rigid part. SmartProfile complies with all current GD&T standards - ASME Y14.5 - 1994, ASME Y14.5 - 2009 and ISO 1101 - including multi-tier position and profile tolerances.

SmartProfile works with point cloud data from any measurement system, allowing direct comparison of measurements made using differing techniques, or at different points in the manufacturing process, in one common format. "Aerospace and medical device manufacturers have saved significant amounts of time and money by incorporating SmartProfile into their global manufacturing/supply chain workflow," said a company spokesperson.

To use SmartProfile, just open the CAD file, identify datums and tolerances, import the point cloud and click Evaluate. SmartProfile does the math. A color-coded chart indicates the status of each measured feature in a Go/No-Go format, and displays the magnitude and direction of any variation. According to the company, SmartProfile assures fully correct and complete application of GD&T tolerances with simultaneous requirements.

SmartProfile 3 features context-sensitive Help, and fully flexible graphical and text reporting with interactive live preview for real-time "what-if" analysis. Its customizable configuration allows any user to organize the window layout to his or her individual liking. In addition, SmartProfile 3 automates and seamlessly integrates data collection in QVI Measure-X and MeasureMind 3D Metrology Software.

For more information contact:

Quality Vision International, Inc.

850 Hudson Ave.

Rochester, NY 14621

585-544-0450

www.qvii.com

www.kotem.com