Precision machine-ready blanks from aluminum, stainless steel, copper and other alloys.

Precision machine-ready blanks are as close as +/-.0005" dimensionally and as close as .0002" flatness, squareness and parallelism. Each blank is cleaned, deburred and individually packaged.

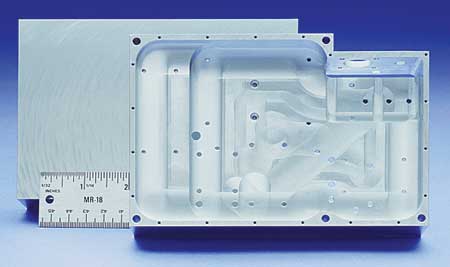

Example of a precision machine-ready blank in the background and the customer's finished part in the foreground.

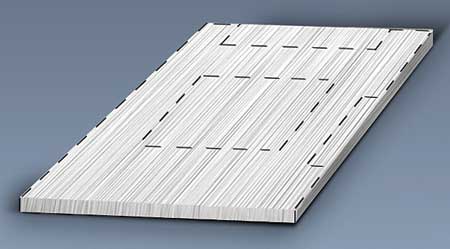

Illustration of a typical precision machine-ready blanks on the left and finish machined part on the right.

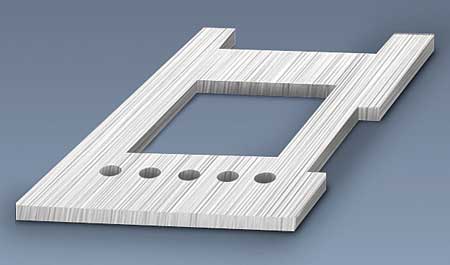

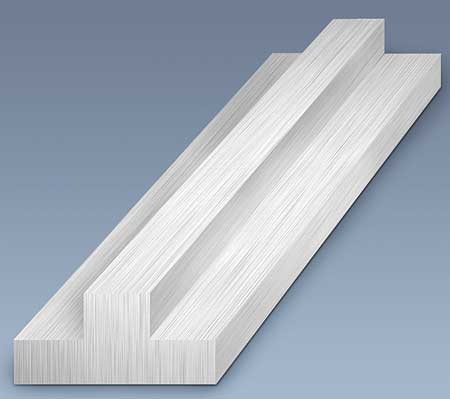

Illustration of a precision machine-ready blanks ordered with added features - two opposing steps.

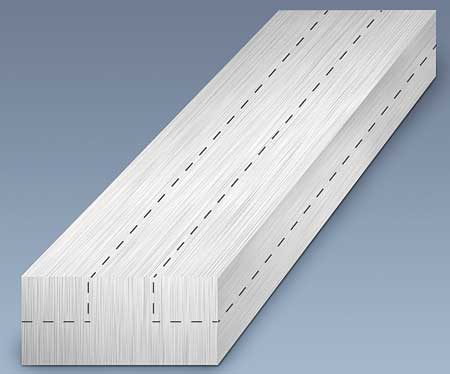

Example of hogging off 13-8 material on a customer supplied part.

TCI Precision Metals has been providing manufacturers with precision machine-ready blanks for over 50 years. "There are still many successful shops who do not know what machine-ready blanks are exactly, or if and when they should be considered," said a company spokesperson. "The following is meant to shed light on the subject and provide some thought provoking questions to help shops determine whether or not precision blanks are right for the next job."

What are ?

Custom machine-ready blanks are made to order based on customers' unique specifications. Typically, they are square, rectangular or round stock milled to custom net specifications. They can be furnished as close as +/-.0005" dimensionally and as close as .0002" in flatness, squareness and parallelism. Machine-ready blanks eliminate the need for squaring up the material prior to finishing the part. Flatness is especially important as it eliminates the tendency for movement during the machining process, especially with large surface area parts. By starting with machine-ready blanks users eliminate the need for specialized machines or tying up machines that are better served performing other operations. Bottlenecks created by time consuming set-up and squaring operations are avoided, saving even more time. This increases shop capacity without adding overhead. Machine-ready blanks arrive to specifications and are ready to go directly from the receiving dock onto the CNC machines. Machine-ready blanks arrive deburred, cleaned and vacuum packaged to eliminate the possibility of any damage in handling and shipping.

When to Consider Machine-Ready Blanks

The decision to use machine-ready blanks should be made in the materials planning phase of the job. "Using machine-ready blanks to produce first articles and then continuing right through production is the best way to insure consistency of process," said the spokesperson. "Since each order of machine-ready blanks is made to order, there are no minimum quantities. As the job ramps to production you can order the quantity needed, to be delivered as you need them."

Production Machining

Although they are also well-suited for prototype and tooling applications, machine-ready blanks are best suited for production machining jobs where the efficiency and time savings from using them can be projected over multiple parts - the more the better. The value of using machine-ready blanks increases with part count as the shop is able to push out more finished parts, faster, by virtually eliminating bottlenecks associated with time consuming material prep work.

Feature-Added Blanks

Feature-added blanks are milled to the same tight tolerances as custom and standard blanks, but include one or more features specified by the customer. A typical added feature might be a large amount of material removal, e.g., milling all six sides of a rectangular machine-ready blank with opposing steps. TCI machine-ready blanks are double disc ground and/or duplex milled so at least two sides of a part are cut at the same time. This translates into a cost savings over facing only one side of raw stock at a time. When the machine-ready blanks arrive with additional features added, less in-house machine time is required.

Customer Furnished Blanks

Quite often there can be a feature on a part that is very time consuming to complete in a shop, for example hogging off 13-8 material. "TCI Precision Metals uses specialty duplex milling to reduce the cutting time to a fraction of what it would typically take on a job shop floor," said the spokesperson. "End costs are reduced by not having to buy expensive cutting tools or inserts and production bottlenecks are avoided, which leads to increased shop capacity.

Are Machine-Ready Blanks Right for You?

"To determine if machine-ready blanks are right for you, ask yourself the following questions:

- Are you a custom precision manufacturing company that could benefit from greater efficiency and increased capacity?

- How much of your expensive high tech equipment is doing low tech prep work?

- How often do you experience production bottle necks associated with prepping material?

- If you eliminated material prep work, how much more production could you move through your shop?

- How much money could you save by eliminating scrap prior to finish machining?

- Would your business benefit from being able to ship faster?

- Do you have part features you would like to see included in a custom machine-ready blank, ready for finish machining?

- If you could have precision machine-ready blank with guaranteed tolerances delivered to your receiving dock, ready to load onto your CNC machines, how much would that benefit your business?

- How much could you reduce your cycle times by only machining critical features?"

Benefits of Machine-Ready Blanks

- Reduce material prep time

- Produce more parts, faster

- Reduce bottlenecks

- Reduce scrap.

For more information contact:

John Belzer, President

TCI Precision Metals

240 E. Rosecrans Ave.

Gardena, CA 90248

800-234-5613 / 310-323-5613

jbelzer@tciprecision.com

www.tciprecison.com