The Short Stop

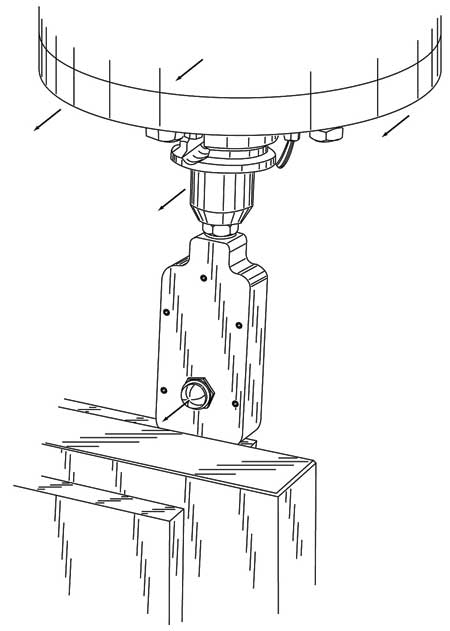

The shank of the Short Stop is designed to be installed in a tool holder.

When the machining is complete, the transmitter is programmed to lower onto anything stationary and the program moves the machine to push the transmitter's button - sending a signal to the receiver.

C&C Manufacturing Corp. saw a recurring issue with idle spindle times, and realized that even small amounts of wasted time can become significant in the long run. The company found a novel way of overcoming the problem.

"We are a job shop running anything from prototypes to long runs," said C&C President Tom Ryan. "We have a few repeat jobs with long run times, 30 minutes each. While the machine is running, the machinist running the job is always tending other machines or performing other duties. The machine would complete the operation and not be noticed. We needed to find a way to let our people know when the machine stopped when they were not near the machine, out of line of sight."

The company needed to find a system that would use the movement of the machine to notify an operator with an audible as well as a visual alert when an operation was complete. It also needed to be mobile and usable on all the company's machines so the operator could move it from one machine to another. Additionally, it needed to withstand the harsh manufacturing environment.

The company soon came to the conclusion that such a product did not exist. "We could not find anything that would meet these requirements," said Ryan. The solution was to design a system, dubbed the Short Stop (patent pending), using existing technology.

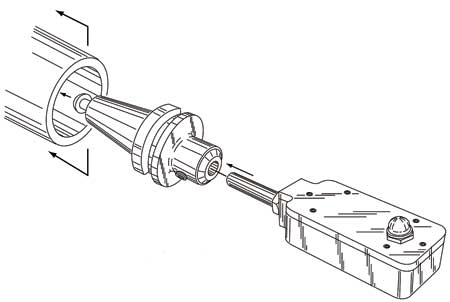

Ryan and his team engineered a watertight housing to hold a transmitter. The housing includes a sealed actuator assembly that is designed to press a button on the transmitter. The Delrin housing has a shank threaded in the top. The shank will fit a tool holder.

When the part is being machined, the transmitter is in the tool changer magazine, away from hot chips and coolant. When the machining is complete, the transmitter is programmed to lower onto anything stationary and the program moves the machine to push the transmitter's watertight button to send a signal to the receiver, sounding the alarm. The operator places the receiver where it can be heard or seen when it signals the alert.

"Before the Short Stop, if the operator was paying strict attention to the machine, we would get 15 parts per shift," said Ryan. "But as time went on it would start to vary, 15 one shift, maybe 12 another. There was no consistency due to idle machine time. After the Short Stop was installed the 15 parts per shift stayed much more consistent."

Short Stop is manufactured by C&C Manufacturing Corp. and is available to manufacturers. A video of the Short Stop in action is available at youtube.com/watch?v=2iHtUBtStxA.

A Short Stop package includes:

- One receiver capable of communicating with up to four transmitters

- One to four transmitters

- Set-up and operating instructions

- Batteries included.

Founded in 1968, C&C Manufacturing Corp. offers milling, turning and inspection capabilities from prototype to production.

For more information contact:

Tom Ryan

C&C Manufacturing Corp.

3737 S Inca St.

Englewood CO 80110

303-761-8660

tryan@candcmfg.com

www.candcmfg.com