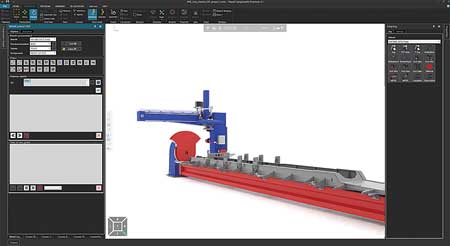

Pema Skytrack

Offline programming

Pema CellControl

Pemamek LLC, U.S. subsidiary of Finnish welding automation provider Pemamek Ltd., will showcase its user-friendly CAD-to-Path welding solutions at FABTECH 2025, booth B35036. The company will offer live demonstrations of the PEMA Skytrack based on real customer applications. Visitors will be able to explore PEMA WeldControl 300 Offline software and experience PEMA CellControl's debut. Pemamek's welding automation experts will be on hand to discuss how these solutions can transform North American shops, regardless of size or industry, and help empower them to boost productivity, enhance weld quality, and address skilled welder shortages while minimizing costly rework.

"Shops continue to face mounting challenges: maintaining consistent weld quality, meeting tight deadlines and finding skilled welders in a shrinking talent pool," said a company spokesperson. "Pemamek's robotic welding solutions, such as the compact PEMA Skytrack paired with intuitive PEMA WeldControl 300 Offline software, for example, deliver automated precision that slashes manual labor, maximizes throughput and virtually eliminates costly post-weld repairs."

The PEMA Skytrack is suited for shops welding heavy steel structures such as buckets, beams, booms or different types of frames. This compact robot welding station integrates a robot track and PEMA Skyhook positioner into a single, easy-to-relocate unit. Servo-driven axes ensure precise, synchronized movements, positioning welds in the optimal flat position for enhanced joint penetration and consistent quality.

Designed for operators of all skill levels, PEMA WeldControl 300 Offline simplifies robotic welding with features such as:

- Offline Programming: Plan and simulate welds without stopping production, saving valuable time

- Laser Seam Scanning: Automatically detects and adapts to weld imperfections for better results

- PathPlanner: Generates collision-free welding paths in seconds, reducing set-up time and boosting efficiency.

These highly automated tools make robotic welding accessible to operators new to automation, allowing shops to train staff quickly and maintain a high level of productivity.

"Debuting at FABTECH 2025, PEMA CellControl redefines robotic welding control with its intuitive, browser-based touchscreen interface," said a company spokesperson. "This advanced software streamlines workflow management, enabling operators to oversee robot stations with unmatched ease and efficiency."

"PEMA Skytrack and CellControl make automation approachable for any shop, with our local team guiding operators every step of the way," said Michael Bell, Sales Director at Pemamek LLC. "All PEMA solutions feature easy-to-learn software and rock-solid technology which, when combined with this hands-on local U.S. support, ensure a smooth integration into any shop's workflow."

For more information contact:

Pemamek LLC

20333 State Hwy. 249, Suite 200

Houston, TX 77070

832-966-0294

info.us@pemamek.com

www.pemamek.com/us

FABTECH Booth B35036