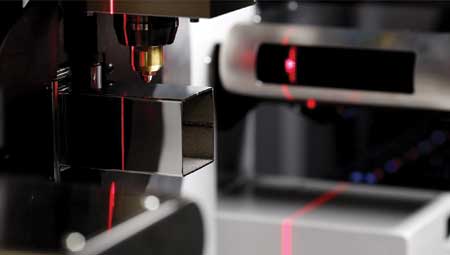

ByTube Star 130 offers fast and precise machining of workpieces from 10 mm to 130 mm.

The Quick Cut and Laserscan functions offer an optimized process for tube processing.

Bystronic offers the ByTube Star 130 laser cutting system, which can help sheet metal production companies quickly enter the tube processing business and thus access new customer groups.

The increased laser power of a new 4 kW offers a faster and more precise cut and overall higher quality throughout the tube processing process. It is suited for a wide range of applications for all metallic materials in sizes from 10 mm to 130 mm and raw material lengths of up to 8.5 m.

"The automated system reduces manual intervention to a minimum, making it particularly easy to get started in tube processing," said a company spokesperson. "At the same time, the machine covers a wide range of requirements: since 85% of the market potential lies in the small tube segment, the ByTube Star 130 is geared toward processing tubes with diameters from 10 mm to 130 mm. The machine has a loading capacity of up to 17 kg per meter. With the 2D cutting head, 90% of all customer requirements can be met, as vertical cuts account for the largest market share. Available in three power levels, 2, 3 or 4 kg, the fiber laser unit of the ByTube Star 130 offers high energy efficiency as well as consistently uniform cutting quality."

Additional options can be configured individually and enable further operating convenience as well as increased production quality:

- Laserscan: Real-time compensation of pipe bending to improve cutting precision in all cutting conditions, even with low-quality material.

- Quick Cut: Greater speed for better performance due to an additional linear axis.

Automatic weld seam detection enables the weld seam to be automatically oriented to the desired position. Via Laserscan, the function independently detects and compensates for geometric deviations of tubes, increasing the accuracy of cutting operations regardless of raw material quality.

With the BySoft Cell Control Tube user interface, Bystronic puts the control of all functions related to the laser cutting of tubes on a touchscreen. Beginners do not need extensive experience to start production on the ByTube Star 130. Cutting jobs are set up quickly, and the interface is intuitive and easy to understand.

BySoft Cell Control Tube builds on the Bystronic software, which Bystronic uses for all other cutting and bending systems. The intuitive software supports users in importing and creating cutting plans, which makes the operation of cutting sequences on the ByTube Star 130 convenient. Visualizing parts and models, creating cutting plans, monitoring production processes, be they small batches or large orders, BySoft Cell Control Tube lets users progress productively from entering orders to delivering finished parts.

For more information contact:

Bystronic Inc.

2200 West Central Road

Hoffman Estates, IL 60192

847-214-0300 / 800-247-3332

sales.us@bystronic.com

www.bystronicusa.com