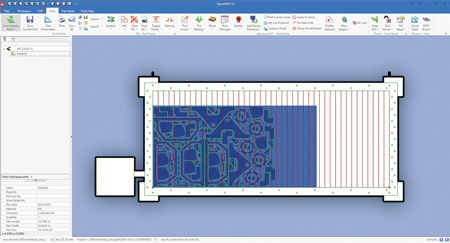

SigmaNEST Machine Bed: View stock in relation to the actual machine bed.

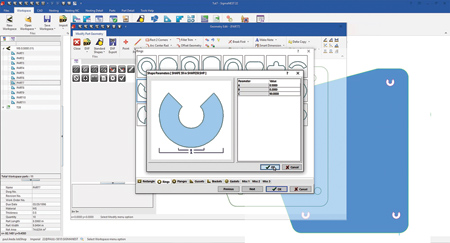

Standard shape library assists super-fast parametric geometry edits.

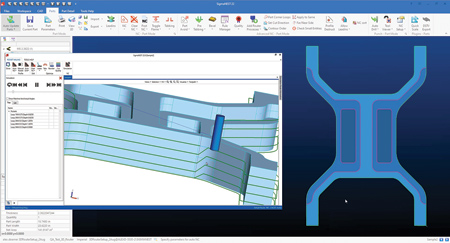

3D-capable router module visualizes pocket depths.

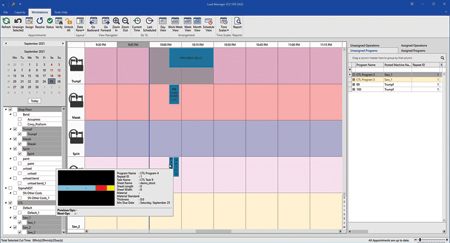

SigmaCTL: Schedule production for each machine and process.

SigmaNEST-Punch-Order - Automatic punch ordering aids part removal.

CAMBRIO has announced version 22 of the SigmaNEST software suite. Across the board improvements enhance all areas of the SigmaSUITE product portfolio, including CAD/CAM nesting for router, bevel, punch and cut-to-length, and also expands Connected Shop capabilities designed to help both large and small fabricators.

A redesigned installer detects all existing products for upgrading. Programmers get a jumpstart with enhanced import capabilities for the latest native CAD formats, such as sketch association to SigmaNEST operations for NX, and 3D part property mapping for SolidWorks. The SigmaNEST shape library has been improved to enable super-fast parametric geometry edits for more efficient CAD programming.

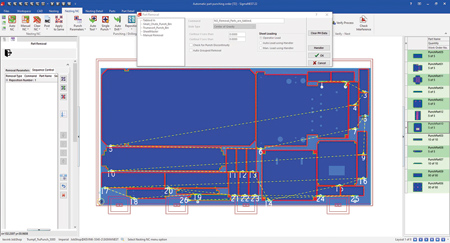

SigmaNEST Version 22 introduces a number of UI enhancements, such as options to change the sheet names in the feature tree; granular control over hatching density for reporting visibility; and multiview layout sequencing. Users can also select the correct Machine Bed Drawing directly from the Machine Parameters Config menu to see their stock in relation to the bed size and slat locations.

SigmaNEST v22 features a graphical indicator to enable users to validate tab locations for the entire nest before sending the NC program to production. Additionally, part reporting capabilities have been extended with support for part process parameters, such as amperage or gas type, improved visual aids for nest detail text and the ability to highlight mirrored parts with hatching styles.

Finally, SigmaNEST has been re-engineered for direct transactions within SigmaSUITE, creating a 30% speed improvement on processes that required SimTrans transaction manager. Customers who do not have an MRP/ERP connection can upgrade without the cost of SimTrans, and those configurations that require an MRP/ERP connection are now much faster.

SigmaNEST Router is now 3D-capable, allowing users to visualize pocket depths, ramping between Z-level depths and tool changes. 3D Router allows users to define the optimum cutting method based on the ratio between part geometry shape and material removal, resulting in fewer passes and a more efficient toolpath. In addition, SigmaNEST 3D Bevel has updated I-Cut control to manage the rotation and tilt so that straight cuts are treated as a zero-degree angle to ensure a perfect edge. Further enhancements include the ability to move lead-in positions for profile destruction to eliminate unsafe head movement, and the ability for bevel programmers to use 2D geometry with the Rule Manager to extrude fixed bevels and easily generate leads, corner loops and transitions.

SigmaNEST Punch has gained several productivity features, including improved nesting for automated common line cutting for single, same and multipart geometry that easily recalculates for different tool sizes. Clamps can now be repositioned on the fly, and a new multitorch simulation allows users to check torch sequence and spacing before production. Automatic punch sequencing for part removal adds new flexible rules such as removing small parts first, or working towards the clamps to retain plate rigidity. Finally, the new tool manager allows tools to be quickly added, saved as a group and ported between jobs.

Other products within the SigmaSUITE portfolio have also seen significant updates. SigmaDEVELOP has added flange collar options to transition from rectangle to round/oval shapes, and the ability to transition zero-radius corners on a rectangle to elliptical shapes. SigmaBEND AP introduces additional machine support, reusable tooling set-ups for future applications and support for 3D assembly filters.

As another integrated piece of the Connected Shop, SigmaCTL is now upgraded for better quoting, job creation and part tracking/unloading. SigmaCTL now works with SigmaSCHEDULE and Load Manager, and is augmented by a new CTL Feedback app to manage programs at the machine. In addition, users can now specify load orientation and mix parts from across jobs to optimize their material savings with the optimum nest. SigmaCTL, along with SigmaTUBE, can now export a 3D nest as either a STEP or IGES files to interface with new machine manufacturers.

The Connected Shop solutions also gain important functionality throughout. SigmaSCHEDULE now analyzes jobs for any items that require secondary operations and prioritizes them to allow for better efficiency, a quicker start in production and reduced idle time. Additionally, Load Manager can now intelligently distribute process tasks within a machine group for better manufacturing capacity with automated load balancing.

SigmaMRP and SigmaQUOTE offer improved user access permissions for a view-only mode, which allows full visibility, but no editing capabilities. Both programs resolve any fractional cost amounts to ensure accurate accounting, and a smart purchasing button allows the user to select multiple jobs to calculate material requirements and combine common elements into a single PO to be used for all jobs. Lastly, estimators can quickly copy items from job to job along with any price adjustments or additional costing factors, which significantly speeds up quoting for similar projects.

For more information contact:

SigmaTEK Systems, LLC

1445 Kemper Meadow Drive

Cincinnati, OH 45240

513-674-0005

info@sigmanest.com

www.sigmanest.com