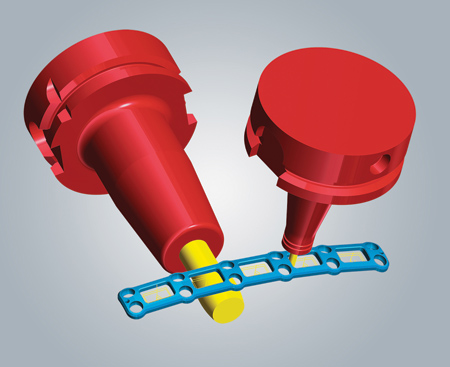

hyperMILL 5-axis swarf cutting is suited for slightly curved surfaces, such as this bone plate.

OPEN MIND Technologies will be featuring its hyperMILL CAD/CAM software suite at MD&M West, booth 2977, at the Anaheim Convention Center, CA, from April 12 to 14, 2022.

"hyperMILL offers medical manufacturers powerful NC programming in applications for 2.5D, 3D and 5-axis machining in prototype and production manufacturing, especially when maximum speed, precision and flexibility are critical," said a company spokesperson.

MD&M attendees can see hyperMILL MAXX Machining, which offers three modules for roughing, drilling and finish milling. hyperMILL MAXX Machining enables high-performance cutting, including in challenging materials, such as titanium and stainless steel alloys. Enabling uninterrupted cutting, OPEN MIND will feature hyperMILL 3D and 5-axis equidistant finishing for machining surfaces with a uniform 3D infeed, resulting in fine surface finishes when used in combination with high precision surface mode and smooth overlap techniques. These finishing strategies are especially suited for high-speed cutting.

Also to be highlighted at the show, the hyperMILL 5-axis swarf cutting and barrel cutter capabilities are suited for slightly curved surfaces, such as those on bone plates. This functionality reduces machining time and optimizes surface finishes.

Parts with similar geometries, such as component families and variants, recurring shape elements, features such as holes or pockets and repetitive processes, provide an opportunity to implement automated CAM programming. hyperMILL automation technology-which helps to reduce programming times, standardize processes, eliminate human error and improve overall throughput-will also be demonstrated at the show.

OPEN MIND will also feature the ADDITIVE Manufacturing capability option in hyperMILL CAM software to support 3D printing/additive processes. hyperMILL with ADDITIVE Manufacturing provides efficient hybrid processing with additive and subtractive processing, including material deposition, on one machine. For complex 5-axis simultaneous processing, hyperMILL ADDITIVE Manufacturing enables an array of flexible options for any directed energy deposition process (DED) such as Wire Arc Additive Manufacturing (WAAM), laser powder, laser hot-wire, electro-beam hot-wire and more. hyperMILL enables users to program the cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps provide reliability.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com

MD&M West Booth 2977